Understanding Welding Symbols

Ray Harkins, The Manufacturing Academy,Garry Pace

2:38:18

Description

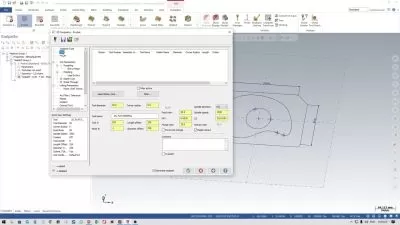

How to Create and Read the Graphical Symbols Used to Define a Welded Joint

What You'll Learn?

- An Overview of the Major Welding Processes including FCAW, SAW, SMAW, GTAW and GMAW

- A Detailed Explanation of Joint Types and Terminology

- Parts of a Welding Symbol: Reference Lines, Arrows and Tails

- Groove Weld Terminology including Groove Shapes and their Associated Symbols

- A Deep Dive into Fillet Welds -- Their Applications and Symbols

- An Overview of Plug, Slot and Stud Welds

- Nondestructive Testing Types and How to Depict Those Tests on an Engineering Drawing

- Supplementary Information and Symbols

- And MUCH MORE!!

Who is this for?

What You Need to Know?

More details

DescriptionWelding symbols are the graphical tools, placed on engineering drawings and specifications, that product engineers and designers use to communicate the intent of their design to the people who are making and inspecting the products. Details like the type, shape, length, thickness, and location of the weld are all communicated through these welding symbols.

And like all symbols, without an understanding of how they work, they're meaningless. But in this course, "Understanding Welding Symbols", we show you how to read and interpret these symbols.

Metallurgist and Licensed Professional Engineer, Garry Pace is the instructor for this course. Over the past 20+ years, Garry has taught thousands of welders, weld inspectors, quality engineers, quality technicians, and other manufacturing professionals the fundamentals of welding, along with its procedures and specifications.

In this course, you will learn:

An overview of the major welding processes like GTAW, GMAW, SMAW, SAW and FACW

All the major weld joint types

The sections of the welding symbols ... what they mean and why they're important

All the terminology and concepts needed to master welding symbols

How groove and fillet welds are specified and dimensioned

How plug, slot, and stud welds are specified and dimensioned

An overview of nondestructive testing methods like ultrasonic, liquid penetrant, x-ray, and magnetic particle inspection

How required NDT methods are specified on blueprints

And much more!!

We've included in this course far more than just the dry theory. We've included real-life examples and practical applications that can only be learned through years of hands-on experience.

So if you're looking to take your welding and metal working skills to the next level by incorporating the more technical aspects of your profession, then this is the class for you.

Sign up today to advance your skillset and advance career in manufacturing!!

Who this course is for:

- Welders and Welding Inspectors

- Welding Engineers

- Manufacturing Professionals

- Production Supervisors

- Manufacturing and Industrial Engineers

- Quality Engineers, Quality Technicians

- Product Designers

Welding symbols are the graphical tools, placed on engineering drawings and specifications, that product engineers and designers use to communicate the intent of their design to the people who are making and inspecting the products. Details like the type, shape, length, thickness, and location of the weld are all communicated through these welding symbols.

And like all symbols, without an understanding of how they work, they're meaningless. But in this course, "Understanding Welding Symbols", we show you how to read and interpret these symbols.

Metallurgist and Licensed Professional Engineer, Garry Pace is the instructor for this course. Over the past 20+ years, Garry has taught thousands of welders, weld inspectors, quality engineers, quality technicians, and other manufacturing professionals the fundamentals of welding, along with its procedures and specifications.

In this course, you will learn:

An overview of the major welding processes like GTAW, GMAW, SMAW, SAW and FACW

All the major weld joint types

The sections of the welding symbols ... what they mean and why they're important

All the terminology and concepts needed to master welding symbols

How groove and fillet welds are specified and dimensioned

How plug, slot, and stud welds are specified and dimensioned

An overview of nondestructive testing methods like ultrasonic, liquid penetrant, x-ray, and magnetic particle inspection

How required NDT methods are specified on blueprints

And much more!!

We've included in this course far more than just the dry theory. We've included real-life examples and practical applications that can only be learned through years of hands-on experience.

So if you're looking to take your welding and metal working skills to the next level by incorporating the more technical aspects of your profession, then this is the class for you.

Sign up today to advance your skillset and advance career in manufacturing!!

Who this course is for:

- Welders and Welding Inspectors

- Welding Engineers

- Manufacturing Professionals

- Production Supervisors

- Manufacturing and Industrial Engineers

- Quality Engineers, Quality Technicians

- Product Designers

User Reviews

Rating

Ray Harkins, The Manufacturing Academy

Instructor's CoursesGarry Pace

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 23

- duration 2:38:18

- Release Date 2022/11/29