Stress Analysis of Tower/Vertical Column Piping System

Anup Kumar Dey

1:37:20

Description

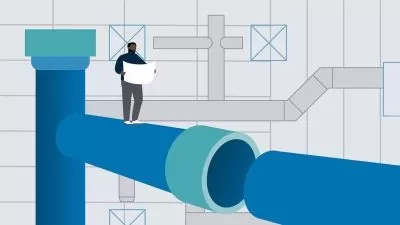

Stress Analysis of Tower/Vertical Column Piping System

What You'll Learn?

- Application of Vertical Columns/Towers

- Inputs Required for Column Piping Stress Analysis

- Creating temperature profile for Column/Tower Piping systems

- Modeling of the Equipment

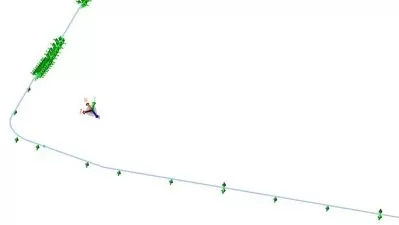

- Clip/Cleat Support Modeling from Towers

- Skirt Temperature Calculation

- Nozzle Load Qualification

- Practical Case Study

Who is this for?

What You Need to Know?

More details

DescriptionThe integrity and reliability of vertical column or tower-connected piping systems are paramount for ensuring the smooth flow of materials and maintaining operational safety. Stress analysis, a crucial aspect of piping design, plays a pivotal role in identifying potential vulnerabilities and ensuring the longevity of these complex systems.

These systems are prevalent in industries such as petrochemicals, oil and gas, and power generation, where vertical columns or towers are connected to intricate piping networks. The vertical orientation imposes unique challenges, as the forces and stresses experienced by the pipes differ significantly from horizontally oriented systems.

Factors Influencing Stress in Vertical Piping Systems:

Gravity Load:

The primary force acting on vertical piping systems is gravity. The weight of the fluid inside the pipes, along with the weight of the pipes themselves, induces stress on the system. Accurate assessment of these loads is critical for ensuring the structural integrity of the entire system.

Thermal Expansion and Contraction:

Fluctuations in temperature can cause pipes to expand or contract, leading to stress. Thermal stress analysis is indispensable for predicting the effects of temperature variations on the system and designing components that can accommodate thermal expansion without compromising structural integrity.

Vibration and Seismic Loads:

Vertical piping systems are susceptible to vibrations induced by operational machinery or seismic events. Analyzing the impact of these dynamic loads on the system is vital to prevent fatigue failure and ensure the system's resilience against unforeseen external forces.

Wind Load:

In outdoor installations, wind loads can significantly affect vertical piping systems. Wind-induced vibrations and lateral forces can cause stress concentrations, especially at pipe supports and connections. Wind load analysis is imperative for designing structures that can withstand these external pressures.

This course will specifically provide information about the following:

What is a Vertical Column or Tower?

Creating Temperature Profiles

Modeling the Equipment

Modeling Cleat Supports

Skirt Temperature Calculation

Nozzle Load Qualification

Practical Case Study

Who this course is for:

- Piping Stress Engineers

- Piping Lead Engineers

- Process and Power Piping Engineers

The integrity and reliability of vertical column or tower-connected piping systems are paramount for ensuring the smooth flow of materials and maintaining operational safety. Stress analysis, a crucial aspect of piping design, plays a pivotal role in identifying potential vulnerabilities and ensuring the longevity of these complex systems.

These systems are prevalent in industries such as petrochemicals, oil and gas, and power generation, where vertical columns or towers are connected to intricate piping networks. The vertical orientation imposes unique challenges, as the forces and stresses experienced by the pipes differ significantly from horizontally oriented systems.

Factors Influencing Stress in Vertical Piping Systems:

Gravity Load:

The primary force acting on vertical piping systems is gravity. The weight of the fluid inside the pipes, along with the weight of the pipes themselves, induces stress on the system. Accurate assessment of these loads is critical for ensuring the structural integrity of the entire system.

Thermal Expansion and Contraction:

Fluctuations in temperature can cause pipes to expand or contract, leading to stress. Thermal stress analysis is indispensable for predicting the effects of temperature variations on the system and designing components that can accommodate thermal expansion without compromising structural integrity.

Vibration and Seismic Loads:

Vertical piping systems are susceptible to vibrations induced by operational machinery or seismic events. Analyzing the impact of these dynamic loads on the system is vital to prevent fatigue failure and ensure the system's resilience against unforeseen external forces.

Wind Load:

In outdoor installations, wind loads can significantly affect vertical piping systems. Wind-induced vibrations and lateral forces can cause stress concentrations, especially at pipe supports and connections. Wind load analysis is imperative for designing structures that can withstand these external pressures.

This course will specifically provide information about the following:

What is a Vertical Column or Tower?

Creating Temperature Profiles

Modeling the Equipment

Modeling Cleat Supports

Skirt Temperature Calculation

Nozzle Load Qualification

Practical Case Study

Who this course is for:

- Piping Stress Engineers

- Piping Lead Engineers

- Process and Power Piping Engineers

User Reviews

Rating

Anup Kumar Dey

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 7

- duration 1:37:20

- Release Date 2024/03/10