About SOLIDWORKSLearn More

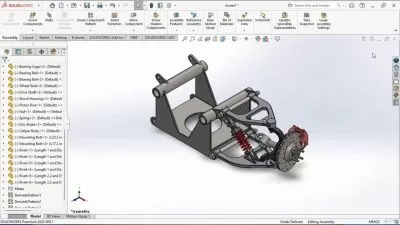

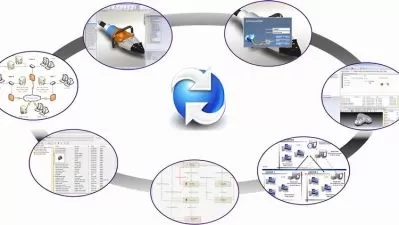

SOLIDWORKS software is a popular tool for product designers and mechanical engineers everywhere. The SOLIDWORKS suite allows you to fully design 3D products and schematics and conduct motion studies of the virtual prototypes. With SOLIDWORKS training on Udemy, top rated instructors can teach you how to utilize this powerful software suite to its full potential.

Sort by:

Sorting

The newest

Most visited

Course time

Subtitle

Filtering

Courses

Udemy

Carlos Aragonés

Finite Element Analysis. SolidWorks Simulation. P5: PIN&CONN 5:27:58

09/29/2024

Subtitle

Pluralsight

Andy Sunseri

Advanced SOLIDWORKS: Solid and Surface Hybrid Modeling 1:29:59

English subtitles

08/31/2024

Subtitle

Linkedin Learning

Gabriel Corbett

SOLIDWORKS 2024 Essential Training 10:00:57

English subtitles

06/19/2024

Subtitle

Udemy

Kabilan A

SOLIDWORKS API Tutorials for Absolute Beginners | ChatGPT 3:20:03

English subtitles

04/29/2024

Subtitle

Udemy

Alen Oletic

SOLIDWORKS SECRETS Course - From Beginner To Advanced 11:57:46

English subtitles

03/26/2024

Subtitle

Udemy

Alen Oletic

Master SURFACING In SOLIDWORKS With Real Life Examples 4:27:35

English subtitles

03/25/2024

Books

Frequently asked questions about SOLIDWORKS

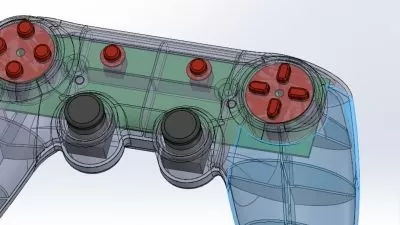

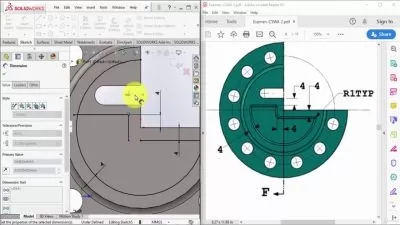

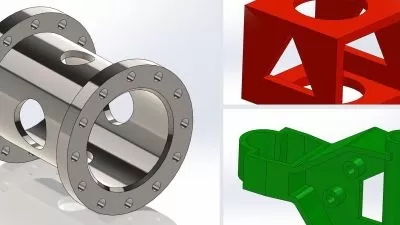

SOLIDWORKS is a computer-aided design (CAD) and computer-aided engineering (CAE) program. SOLIDWORKS specializes in creating 3D models of solid objects like metal parts, plastic components, and 3D-printed objects. Designers and engineers use SOLIDWORKS to create component designs and simulate how different components move and fit together. This ensures that the final product design works exactly as intended. In addition, engineers can use SOLIDWORKS to test how a product will perform over its lifecycle. Designers also use SOLIDWORKS to manage complex projects involving large teams. As many designers submit their individual contributions, project managers use SOLIDWORKS to combine many components and ensure that the final product design looks and works as intended.

SOLIDWORKS is most popular among mechanical engineers because the software helps design objects that consist of many components. Mechanical engineers also take advantage of the software’s simulation capabilities that allow designers to test how a part will perform over its lifecycle. SOLIDWORKS is also used in many other industries that design complex, high-precision products. These include the medical device, automotive, rail, mining, manufacturing, oil and gas, and aerospace industries.

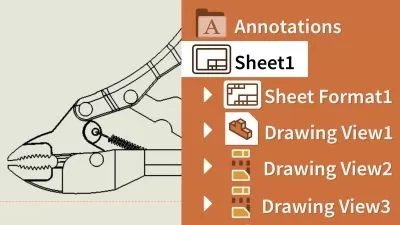

If you are already familiar with the basics of component design, you’ll find you can apply a lot of the concepts you know to SOLIDWORKS (for example, part assemblies). Additionally, those already familiar with AutoCAD and other CAD programs may find it easier to learn SOLIDWORKS. That said, if you’re new to both component design and CAD software, there are many online courses for complete beginners that can help. These courses will guide you through the basics of SOLIDWORKS and introduce you to CAD fundamentals like layers and views. After you finish a beginners’ course, you should be able to create simple designs. Then you can decide whether you want to learn the more advanced features of SOLIDWORKS.

SOLIDWORKS is best suited for designs that involve many components that need to fit together. It helps designers get very detailed information about components and assemblies, such as tolerances, weights, and centers of gravity. While it’s possible to generate 2D drawings and views with SOLIDWORKS, this is not the primary focus of the program. AutoCAD is the best choice for creating and editing 2D graphics. Compared to SOLIDWORKS, it’s much easier to create a design in AutoCAD using lines and annotations. This is one reason why AutoCAD is so widely used early in the design process. While it’s possible to measure and calculate detailed information about materials and assemblies in AutoCAD, this is not the program's primary purpose. In other words, SOLIDWORKS is a full-featured 3D modeling program with limited 2D capabilities. On the other hand, AutoCAD is a full-featured 2D drafting program with some limited 3D capabilities.

Parametric programs like SOLIDWORKS allow you to assign attributes (parameters) to different components of your design. Common properties include length, width, diameter, thickness, and material density. It’s then possible to change attributes later in the design process. For example, suppose that you are designing a metal pipe. One important design factor is the pipe thickness, which is specified by the client. After you’ve already completed the design, the client wants to increase the pipe thickness. With a parametric design program like SOLIDWORKS, it’s possible to enter in the new pipe thickness. SOLIDWORKS then automatically changes the entire pipe design to reflect the changes, including all drawings and views. In a non-parametric program, you would need to manually change each drawing to show the new pipe thickness.