SolidCam CAD CAM and CNC Programming

Technical School Online Technology Training Center

26:02:23

Description

Solidcam advanced manufacturing style CNC programming

What You'll Learn?

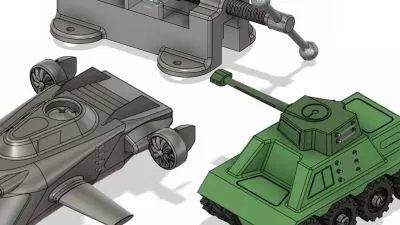

- What is SolidCam and design SW part and Solidcam 2D milling operation

- Fundamentals of Manufacturing

- Manufacturing process

- Advanced manufacturing technologies

- Cutting and Spindle speed decision making

- Cutting time optimization

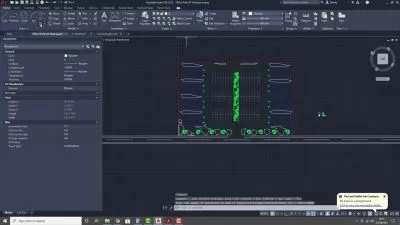

- CNC Programming G Code

- SolidCam milling

- High speed toolpath in 2 and 3 Axis

- Effective Exercises (Free File Download)

- iMachining

- 3D HSR Roughing and Rest Rough Toolpath

- 3D HSM Toolpath

- HSS High Speed Surface Machining

- Milling Operation Examples

- Multi Axis Operations

- Sim 5 Axis Milling

Who is this for?

What You Need to Know?

More details

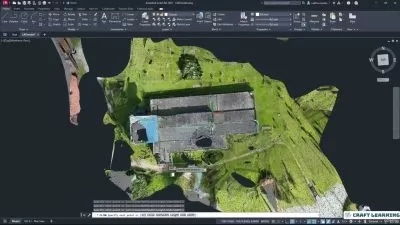

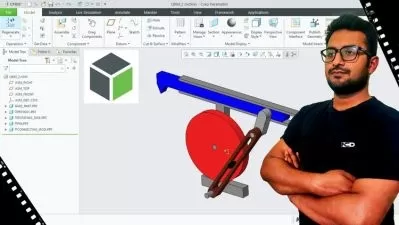

DescriptionSolidCAM is the leading Integrated CAM software which runs directly inside SOLIDWORKS and Autodesk Inventor, with seamless integration and full tool path associativity.

With the single-window integration, all machining operations can be defined and verified without leaving the parametric CAD assembly environment you're used to.

Solidcam software has the easiest interface and is the easiest to learn software in the world. This software, which is used by many small and medium sized companies, works integrated with the Solidworks software, which is the most used in the design world.

With the help of this training set, you can be an advanced Solidcam user starting from scratch. The feature of our training set is that it does not only mention what the commands are for, and all subjects are reinforced with various industry applications where all commands are used. With this training set, you can turn your dreams into reality.

When you watch the training videos, you will be able to learn CNC working logic, M, G codes, 2D and 3D design, 2½ axis milling, 3 axis milling, 4 and 5 axis milling, iMachining features with industrial applications.

You can save up to 80% with iMachining toolpaths developed exclusively by Solidcam software.

Who Can Use: Engineers, Technical Staff, Hobbyists, CNC operators and Job seekers.

Who this course is for:

- Engineers

- Mechanical Engineer

- Production engineer

- Designers ( for producible products )

- Industry Person

- Person of Working on the Manufacturing process

SolidCAM is the leading Integrated CAM software which runs directly inside SOLIDWORKS and Autodesk Inventor, with seamless integration and full tool path associativity.

With the single-window integration, all machining operations can be defined and verified without leaving the parametric CAD assembly environment you're used to.

Solidcam software has the easiest interface and is the easiest to learn software in the world. This software, which is used by many small and medium sized companies, works integrated with the Solidworks software, which is the most used in the design world.

With the help of this training set, you can be an advanced Solidcam user starting from scratch. The feature of our training set is that it does not only mention what the commands are for, and all subjects are reinforced with various industry applications where all commands are used. With this training set, you can turn your dreams into reality.

When you watch the training videos, you will be able to learn CNC working logic, M, G codes, 2D and 3D design, 2½ axis milling, 3 axis milling, 4 and 5 axis milling, iMachining features with industrial applications.

You can save up to 80% with iMachining toolpaths developed exclusively by Solidcam software.

Who Can Use: Engineers, Technical Staff, Hobbyists, CNC operators and Job seekers.

Who this course is for:

- Engineers

- Mechanical Engineer

- Production engineer

- Designers ( for producible products )

- Industry Person

- Person of Working on the Manufacturing process

User Reviews

Rating

Technical School Online Technology Training Center

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 119

- duration 26:02:23

- English subtitles has

- Release Date 2023/08/25