Quality Process Audit & control for PCBA Wave Solder & Test

Evelyn 7E academy

1:55:34

Description

Audit Wave solder/Test PCBA manufacturing line with a comprehensive QPA checklist contain > 300 control points provided

What You'll Learn?

- Understand the PCBA Wave Solder & test process control through QPA checklist questions

- Conduct Quality Process Audit for PCBA Wave Solder & test manufacturing line

- Apply key process control to PCBA Wave Solder & test process

- Minimize potential failure associated to PCBA Wave Solder & test through rigorous process input control

- Achieve consistently good quality product PCBA Wave Solder & test process

Who is this for?

More details

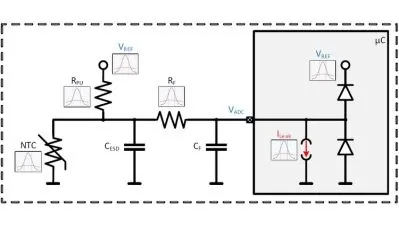

DescriptionWave soldering is used for to attach through hole component and glue mount surface mount component onto the PCBA. Wave soldering process start from component preparation , insert into PCBA which could already have SMT component on pallet, After the insertion is component, inspection is done to ensure the component are inserted correctly and then it will feed into a wave solder machine. Wave soldering are normally done in big batches. A single mistake in the process could potentially created a whole batch of defect product which will need to be reworked or even scrapped. That's why it's essential to have a well-established process set up and in control in the PCBA Wave soldering process .

After a PCBA is completed, the board will go inspection and test process which include ICT and FCT had to set up correctly to effectively screen out defect and does get to the customer.

I have created a comprehensive course that will teach you everything you need to know about the process control, and quality audit of a wave solder & test in PCBA process. With my experience in auditing and working with more than 100 manufacturers and their suppliers globally PCBA process control, I have developed a quality audit checklist with process control points translated into over 300 questions for a PCBA wave solder & test process. This checklist is designed based on my experience and a pool of subject matter expert knowledge in PCBA process and quality process audit from all the previous companies I have served.

In this course, you will uncover all the secrets of process control in each PCBA wave solder and test process step and learn how to monitor process output to achieve consistently good quality products in PCBA process. After all, consistent good quality parts are the king in all businesses, and this course will help you achieve that. Get ready to apply what you have learn in this course about PCBA wave solder and test process control and help the PCBA to create a consistently good quality product through powerful techniques to set up, control and monitor the process

Who this course is for:

- Supplier quality engineers/professionals for PCBA

- Procurement professionals/engineers for PCBA

- PCBA process quality engineer

- PCBA process engineer

- PCBA production engineer

Wave soldering is used for to attach through hole component and glue mount surface mount component onto the PCBA. Wave soldering process start from component preparation , insert into PCBA which could already have SMT component on pallet, After the insertion is component, inspection is done to ensure the component are inserted correctly and then it will feed into a wave solder machine. Wave soldering are normally done in big batches. A single mistake in the process could potentially created a whole batch of defect product which will need to be reworked or even scrapped. That's why it's essential to have a well-established process set up and in control in the PCBA Wave soldering process .

After a PCBA is completed, the board will go inspection and test process which include ICT and FCT had to set up correctly to effectively screen out defect and does get to the customer.

I have created a comprehensive course that will teach you everything you need to know about the process control, and quality audit of a wave solder & test in PCBA process. With my experience in auditing and working with more than 100 manufacturers and their suppliers globally PCBA process control, I have developed a quality audit checklist with process control points translated into over 300 questions for a PCBA wave solder & test process. This checklist is designed based on my experience and a pool of subject matter expert knowledge in PCBA process and quality process audit from all the previous companies I have served.

In this course, you will uncover all the secrets of process control in each PCBA wave solder and test process step and learn how to monitor process output to achieve consistently good quality products in PCBA process. After all, consistent good quality parts are the king in all businesses, and this course will help you achieve that. Get ready to apply what you have learn in this course about PCBA wave solder and test process control and help the PCBA to create a consistently good quality product through powerful techniques to set up, control and monitor the process

Who this course is for:

- Supplier quality engineers/professionals for PCBA

- Procurement professionals/engineers for PCBA

- PCBA process quality engineer

- PCBA process engineer

- PCBA production engineer

User Reviews

Rating

Evelyn 7E academy

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 10

- duration 1:55:34

- Release Date 2023/05/06