Pump Piping and Stress Analysis

Atul Singla

2:34:46

Description

Pump Layout Design and Stress Analysis

What You'll Learn?

- Pump Piping and Layouts

- Aspects of Pump piping

- Visualization of Pump Piping via 3D model snaps

- Stress Analysis for Pump Piping

Who is this for?

What You Need to Know?

More details

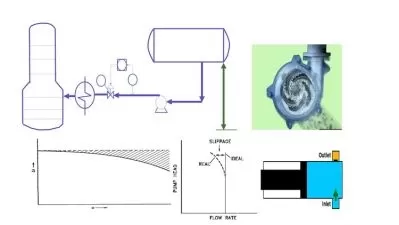

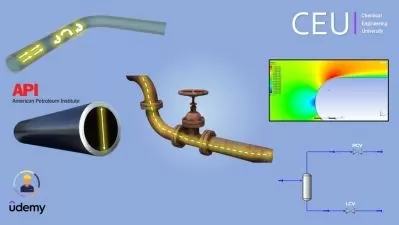

DescriptionCourse on Pump Piping and Stress Analysis has been divided into two sections: Layout and Stress Analysis. In the beginning basic fundamentals related to Pump Layout and Piping are explained. Common issues related to NPSH and Cavitation are discussed in detail. Various configurations recommended with respect to temperature and sizes are drawn and explained with the help of 3D views and sketches.

Following Modules have been captured and explained in this Section:

What is a Pump? & Common types of Pumps used in our Industry.

What is NPSH & Possible Solutions for NPSH problems

What is Cavitation and What are the major causes?

Important Components on Pump Suction Piping.

Discussion on Pump Layout and Piping

Layout aspects of Pump Piping

Pump Spacing Criteria

Pump Seal Concepts

Stress recommendations

Model/Pictorial views

Stress Analysis: Complete content is prepared by Mr. Anup Dey (Special Thanks for valuable contribution)\

Various concepts related to Stress Analysis keeping in view the pump piping have been captured and explained in detail.

Actual modelling in CAESAR II is done and explained in detail w.r.t. industry practices and various codes & standards.

Following major activities have been captured

Setting Ground Work

Documents/Input Required

Input parameters in Caesar

Settings Unit Systems

·Codes & Standards used

Step By Step Modelling

Various tools of Caesar II

Pipeline, Fittings, Supports

Best Practices while modeling/Analysis

Modeling of Pump Piping

Load Cases, Caesar Results and Reports

Creating Load Cases, w.r.t. Various parameters

Analyzing Caesar results

Generating stress reports

Concluding Stress Results and Reports

Who this course is for:

- Piping Design engineers & designers, Mechanical Engineers

Course on Pump Piping and Stress Analysis has been divided into two sections: Layout and Stress Analysis. In the beginning basic fundamentals related to Pump Layout and Piping are explained. Common issues related to NPSH and Cavitation are discussed in detail. Various configurations recommended with respect to temperature and sizes are drawn and explained with the help of 3D views and sketches.

Following Modules have been captured and explained in this Section:

What is a Pump? & Common types of Pumps used in our Industry.

What is NPSH & Possible Solutions for NPSH problems

What is Cavitation and What are the major causes?

Important Components on Pump Suction Piping.

Discussion on Pump Layout and Piping

Layout aspects of Pump Piping

Pump Spacing Criteria

Pump Seal Concepts

Stress recommendations

Model/Pictorial views

Stress Analysis: Complete content is prepared by Mr. Anup Dey (Special Thanks for valuable contribution)\

Various concepts related to Stress Analysis keeping in view the pump piping have been captured and explained in detail.

Actual modelling in CAESAR II is done and explained in detail w.r.t. industry practices and various codes & standards.

Following major activities have been captured

Setting Ground Work

Documents/Input Required

Input parameters in Caesar

Settings Unit Systems

·Codes & Standards used

Step By Step Modelling

Various tools of Caesar II

Pipeline, Fittings, Supports

Best Practices while modeling/Analysis

Modeling of Pump Piping

Load Cases, Caesar Results and Reports

Creating Load Cases, w.r.t. Various parameters

Analyzing Caesar results

Generating stress reports

Concluding Stress Results and Reports

Who this course is for:

- Piping Design engineers & designers, Mechanical Engineers

User Reviews

Rating

Atul Singla

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 8

- duration 2:34:46

- English subtitles has

- Release Date 2024/05/07