Process equipment essentials for a successful career start

WR Training

6:21:24

Description

Overview of pipe valves vessels tanks heat exchangers pumps compressors distillation steam traps strainers and much more

What You'll Learn?

- Understand how the various types of valves work (gate, globe, plug, ball, diaphragm...)

- Understand the main components of control valves and how they work

- Understand the concept of failure mode in control valves : Fail Open "FO", Fail Closed "FC", Fail As Is "FAI"

- Understand the concept of "Air-to-push-up" and Air-to-push-down" in control valves

- Understand how the various valve actuators work

- Understand how safety and pressure relief valves work

- Understand how steam traps work and why they are essentials in steam systems (Floating, Thermostatic, Thermodynamic and Inverted Bucket traps)

- Understand how strainers work (Wye and Basket strainers)

- Understand how the various heat exchanger types work (shell and tube, double pipe, plate and frame, kettle reboiler...)

- Know, understand and interpret TEMA standards and terminologies for shell and tube heat exchangers

- Understand how cooling towers work and their major components

- Understand how fired heaters and furnaces work

- Understand how distilling columns work

- Understand how centrifugal pumps work

- Understand how positive displacement rotary pumps work (gear, lobe, vane, screw...)

- Understand how positive displacement reciprocating pumps work (plunger, diaphragm, piston...)

- Understand how dynamic compressors work (axial and centrifugal)

- Understand how positive displacement rotary compressors work (lobe, vane, screw...)

- Understand how positive displacement reciprocating compressors work (plunger, diaphragm, piston...)

- Understand how flare systems work and their safety rationale

- Test your knowledge with 200+ question quiz

Who is this for?

More details

DescriptionThe general knowledge as to how process equipment really functions is disappearing from the process industries. This is not only our opinion but the general view of senior technical managers in many large corporations.

Chemical process equipment is basically the same now as it was in the 1930s.

The distilling columns, KO drums, compressors, pumps, heat exchangers, valves, steam systems have not changed, and probably will not change.

The fundamental nature of process equipment operation has been well established for a very long time.

The chemical engineer has traditionally been the guardian of process knowledge. So, one would suppose that if fundamental process knowledge is vanishing, the origin of the problem may lie in our universities.

But in this online course, we have gone back to the very simplest basis for understanding process equipment. In every section and video lecture we have said: “Here is how the equipment behaves in the field, and this is why.â€

The guiding idea of our course is that it is better to have a working knowledge of a few simple ideas than a superficial knowledge of many complex theoretical subjects.

In this course, you will find valuable insights into the working principles and construction details of the following process equipment:

Piping systems

Valves

Control valves

Actuators

Safety and pressure relief valves

Steam traps

Strainers

Heat exchangers

Fired heaters

Centrifugal pumps

Positive displacement pumps (rotary and reciprocating)

Dynamic compressors (axial and centrifugal)

Positive displacement compressors (rotary and reciprocating)

Distilling columns

Tanks and vessels

Flare systems

The course includes:

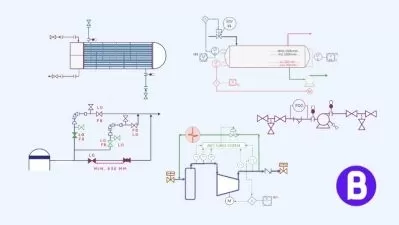

extensive graphics

cross-sectional views

3D animations

This will give you a virtual practical exposure on process equipment.

In addition, we have included at the end of the course a technical quiz (200+ questions) to help you test your knowledge and emphasize the key learning points.

The quiz includes:

True/False questions

Multi-choice questions

Images, cross-sectional views

Solved problems

and much more...

So when you think you’ve got a good grasp on a topic within the course, you can test your knowledge by taking the quiz. If you pass, wonderful ! If not, you can review the videos and notes again or ask us for help in the Q&A section.

Lastly, we hope and believe that this valuable course will help you do a better job and will help you contribute to the safety of your facility, your fellow workers and yourself.

We promise you that even though this is a technical training, you can watch it easily, without pain, but with comprehension, and that after completing it, you won't be an experienced operator or process engineer but you will be prepared to become one if that is what you like and persist to be.

Thank you again for your interest in our online courses. It is a privilege to serve you and make sure that you're learning valuable information with us.

WRÂ Training

Spread the wings of your knowledge

Who this course is for:

- Freshly graduated engineers (mechanical, process and chemical)

- Newly hired plant operators

The general knowledge as to how process equipment really functions is disappearing from the process industries. This is not only our opinion but the general view of senior technical managers in many large corporations.

Chemical process equipment is basically the same now as it was in the 1930s.

The distilling columns, KO drums, compressors, pumps, heat exchangers, valves, steam systems have not changed, and probably will not change.

The fundamental nature of process equipment operation has been well established for a very long time.

The chemical engineer has traditionally been the guardian of process knowledge. So, one would suppose that if fundamental process knowledge is vanishing, the origin of the problem may lie in our universities.

But in this online course, we have gone back to the very simplest basis for understanding process equipment. In every section and video lecture we have said: “Here is how the equipment behaves in the field, and this is why.â€

The guiding idea of our course is that it is better to have a working knowledge of a few simple ideas than a superficial knowledge of many complex theoretical subjects.

In this course, you will find valuable insights into the working principles and construction details of the following process equipment:

Piping systems

Valves

Control valves

Actuators

Safety and pressure relief valves

Steam traps

Strainers

Heat exchangers

Fired heaters

Centrifugal pumps

Positive displacement pumps (rotary and reciprocating)

Dynamic compressors (axial and centrifugal)

Positive displacement compressors (rotary and reciprocating)

Distilling columns

Tanks and vessels

Flare systems

The course includes:

extensive graphics

cross-sectional views

3D animations

This will give you a virtual practical exposure on process equipment.

In addition, we have included at the end of the course a technical quiz (200+ questions) to help you test your knowledge and emphasize the key learning points.

The quiz includes:

True/False questions

Multi-choice questions

Images, cross-sectional views

Solved problems

and much more...

So when you think you’ve got a good grasp on a topic within the course, you can test your knowledge by taking the quiz. If you pass, wonderful ! If not, you can review the videos and notes again or ask us for help in the Q&A section.

Lastly, we hope and believe that this valuable course will help you do a better job and will help you contribute to the safety of your facility, your fellow workers and yourself.

We promise you that even though this is a technical training, you can watch it easily, without pain, but with comprehension, and that after completing it, you won't be an experienced operator or process engineer but you will be prepared to become one if that is what you like and persist to be.

Thank you again for your interest in our online courses. It is a privilege to serve you and make sure that you're learning valuable information with us.

WRÂ Training

Spread the wings of your knowledge

Who this course is for:

- Freshly graduated engineers (mechanical, process and chemical)

- Newly hired plant operators

User Reviews

Rating

WR Training

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 137

- duration 6:21:24

- Release Date 2022/12/24