Petroleum Production chemicals

8:26:49

Description

inhibit corrosion, control microbial activity (biocide), scavenge , scale inhibitor , oil Demulsifier

What You'll Learn?

- chemicals designed to inhibit corrosion, control microbial activity (biocide)

- chemicals designed to Oxygen scavenge ,hydrogen sulfied scavenge , control scaling(scale inhibitor)and/or oil Demulsifierle inhibitor), an

- The performance verification of chemical treatment programs

- how to choose injection loation

Who is this for?

What You Need to Know?

More details

Description• Chemical treatment involves the planned addition of a site-specific combination of chemicals. The treatment may include chemicals designed to inhibit corrosion, control microbial activity (biocide), Oxygen scavenge ,hydrogen sulfied scavenge , control scaling(scale inhibitor), and/or oil Demulsifier,The performance of chemical treatment programs must be verified. The two most common application methods used for chemical treatments are continuous injection and batch treatment.

• Corrosion inhibitors are substances that are added to a pipeline to reduce the corrosion rate).

• Biocides are used to mitigate various microbiological problems.

• Scavengers are used to react with a particular potentially corrosive species making it unavailable to participate in corrosion reactions. The two most commonly used scavengers in the oil and gas industry are oxygen and H2S scavengers.

• Scaling occurs when water constituents combine to form insoluble compounds which are then deposited on the pipe wall. Typical scales include calcium carbonate, calcium sulfate, and barium sulfate and scale inhibitor prevent this formation to occurs

• Dehydration chemicals, or demulsifiers, are chemical compounds that are widely used to destabilize, and assist in coalescence of, crude-oil emulsions.

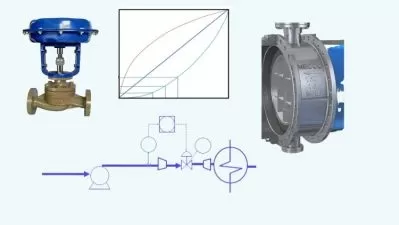

• Treatment chemicals are injected continuously when a specified concentration of chemical is desired in the fluids being transported. Continuous injection requires the installation of chemical pumps and other equipment including a chemical holding tank, a control unit, control interface, and potentially a mixer and flow meter.

• Chemical injection can be performed through an open tube or quill or using an atomizing nozzle. Atomizing nozzles are used to disperse a chemical into the gas phase. Where top-of-line corrosion is occurring, it may be necessary to inject the treatment chemical into the gas phase. If chemicals are added directly to the line (i.e., not using a tube or quill), corrosion may occur at the site of chemical injection. The materials within the injection system should be compatible with the product (e.g., storage tanks, elastomers, tubing, etc.) The most effective position for chemical injection is the center of the pipe or vessel.

• Batch treatments are designed to lay down an inhibition film to provide protection between treatments. Chemicals are typically pumped into the pipeline at a high concentration (generally, tens of thousands of parts per million) for a brief period of time.

Who this course is for:

- oil and gas operator , engineers , beginner , student, technologist

- mangers, Technicians, Chemical and petroleum industry specialists

• Chemical treatment involves the planned addition of a site-specific combination of chemicals. The treatment may include chemicals designed to inhibit corrosion, control microbial activity (biocide), Oxygen scavenge ,hydrogen sulfied scavenge , control scaling(scale inhibitor), and/or oil Demulsifier,The performance of chemical treatment programs must be verified. The two most common application methods used for chemical treatments are continuous injection and batch treatment.

• Corrosion inhibitors are substances that are added to a pipeline to reduce the corrosion rate).

• Biocides are used to mitigate various microbiological problems.

• Scavengers are used to react with a particular potentially corrosive species making it unavailable to participate in corrosion reactions. The two most commonly used scavengers in the oil and gas industry are oxygen and H2S scavengers.

• Scaling occurs when water constituents combine to form insoluble compounds which are then deposited on the pipe wall. Typical scales include calcium carbonate, calcium sulfate, and barium sulfate and scale inhibitor prevent this formation to occurs

• Dehydration chemicals, or demulsifiers, are chemical compounds that are widely used to destabilize, and assist in coalescence of, crude-oil emulsions.

• Treatment chemicals are injected continuously when a specified concentration of chemical is desired in the fluids being transported. Continuous injection requires the installation of chemical pumps and other equipment including a chemical holding tank, a control unit, control interface, and potentially a mixer and flow meter.

• Chemical injection can be performed through an open tube or quill or using an atomizing nozzle. Atomizing nozzles are used to disperse a chemical into the gas phase. Where top-of-line corrosion is occurring, it may be necessary to inject the treatment chemical into the gas phase. If chemicals are added directly to the line (i.e., not using a tube or quill), corrosion may occur at the site of chemical injection. The materials within the injection system should be compatible with the product (e.g., storage tanks, elastomers, tubing, etc.) The most effective position for chemical injection is the center of the pipe or vessel.

• Batch treatments are designed to lay down an inhibition film to provide protection between treatments. Chemicals are typically pumped into the pipeline at a high concentration (generally, tens of thousands of parts per million) for a brief period of time.

Who this course is for:

- oil and gas operator , engineers , beginner , student, technologist

- mangers, Technicians, Chemical and petroleum industry specialists

User Reviews

Rating

Udemy

View courses Udemy- language english

- Training sessions 22

- duration 8:26:49

- Release Date 2025/02/23