Mastering Piping Valve Material Specifications (VMS)

Atul Singla

10:32:19

Description

Valve Material Specification (VMS) for Piping Engineers

What You'll Learn?

- Valve Material Specification (VMS): How to Prepare VMS

- Valve Numbering System

- Valve Index

- Valve Datasheet

- API 600

- API 6D

- API 598

- Components of API 600 Gate Valves

- Components of API 602 Gate Valves

- Components of API 6D Gate Valves

- Components of API 6A Gate Valves

- Material of Construction for Valves (CS, LTCS, AS & High Temperature Carbon steel)

Who is this for?

What You Need to Know?

More details

DescriptionDiscover the comprehensive Valve Material Specification (VMS) course tailored specifically for piping engineers involved in the selection, design, and specification of valves for industrial applications. Gain an in-depth understanding of the requirements and standards that govern valve selection and procurement, equipping you with the knowledge and skills necessary for optimal valve material specifications.

Sections of the Course on VMS:

Scope: Explore the essential scope and objectives of the Valve Material Specification (VMS) course, emphasizing the significance of proper valve selection and material specifications in ensuring safe and efficient piping system operations.

Abbreviation: Familiarize yourself with industry-specific abbreviations and acronyms relevant to valve material specifications, enhancing your understanding of the terminology used in valve engineering.

Reference Documents: Introduce yourself to the vital reference documents that serve as the foundation for valve material specifications. Gain insight into industry codes, standards, and guidelines essential for selecting suitable valves for specific applications.

Valve Numbering System: Understand the importance of the valve numbering system for identification and traceability purposes. Acquire knowledge of the valve numbering system's role in facilitating efficient valve management throughout the lifecycle of a piping system.

General Notes: Grasp the significance of including specific instructions, requirements, and limitations in the general notes of valve material specifications. Ensure accurate valve selection and procurement by incorporating crucial details in your specifications.

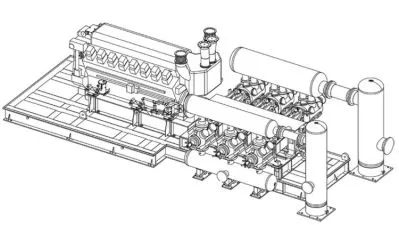

Attachments: Gain an understanding of the crucial role attachments play in valve material specifications. Learn how to effectively interpret and utilize various attachments such as drawings, diagrams, and technical datasheets to enhance your specification process.

Valve Index: Appreciate the significance of valve indexing for accurate record-keeping, streamlined maintenance activities, and smooth piping system operations. Develop an understanding of how valve indexing functions within valve material specifications.

Valve Datasheets: Master the art of reading, interpreting, and creating valve datasheets. Discover the critical parameters to consider when selecting valves based on their specifications, materials, and performance characteristics.

Inspection Requirements: Comprehend the importance of inspection requirements in ensuring compliance with specifications, standards, and quality assurance. Familiarize yourself with the various testing and inspection methods employed during valve procurement and fabrication processes.

Material Section of Valves: Dive into the material section of valves, delving into the selection criteria for different materials. Explore the chemical and mechanical properties of materials like carbon steel, low-temperature carbon steel, stainless steel, and high-temperature carbon steel. Understand the relevant ASTM standards associated with each material type.

Anatomy of Gate Valves: Explore the anatomy of gate valves according to API standards. Gain knowledge about the 17 components specified by API 600, the 58 components specified by API 602, and the 14 components specified by API 6D and API 6A. Enhance your understanding of gate valves and their components.

API Standards: Discover the API standards applicable to valve material specifications, including API 600 and API 6D. Understand the requirements and guidelines outlined in these standards to ensure proper valve selection and material specifications.

Valve Trims and Non-Trims: Learn the material selection criteria for valve trims and non-trims. Explore the significance of selecting appropriate materials for valve internals to achieve optimal performance and durability.

Trims and Non-Trims Identifications: Master the methods and markings used to identify valve trims and non-trims. Understand how to interpret and recognize different trim materials based on industry standards and specifications.

Information Sources and Sequences: Gain insights into various sources of information available for valve material specifications. Understand the sequence of steps involved in extracting relevant clauses and tables from API standards and other reference documents.

Embark on the Valve Material Specification (VMS) course and emerge equipped with the knowledge and skills to create, interpret, and implement valve material specifications effectively as a proficient piping engineer.

Who this course is for:

- Piping Engineering

Discover the comprehensive Valve Material Specification (VMS) course tailored specifically for piping engineers involved in the selection, design, and specification of valves for industrial applications. Gain an in-depth understanding of the requirements and standards that govern valve selection and procurement, equipping you with the knowledge and skills necessary for optimal valve material specifications.

Sections of the Course on VMS:

Scope: Explore the essential scope and objectives of the Valve Material Specification (VMS) course, emphasizing the significance of proper valve selection and material specifications in ensuring safe and efficient piping system operations.

Abbreviation: Familiarize yourself with industry-specific abbreviations and acronyms relevant to valve material specifications, enhancing your understanding of the terminology used in valve engineering.

Reference Documents: Introduce yourself to the vital reference documents that serve as the foundation for valve material specifications. Gain insight into industry codes, standards, and guidelines essential for selecting suitable valves for specific applications.

Valve Numbering System: Understand the importance of the valve numbering system for identification and traceability purposes. Acquire knowledge of the valve numbering system's role in facilitating efficient valve management throughout the lifecycle of a piping system.

General Notes: Grasp the significance of including specific instructions, requirements, and limitations in the general notes of valve material specifications. Ensure accurate valve selection and procurement by incorporating crucial details in your specifications.

Attachments: Gain an understanding of the crucial role attachments play in valve material specifications. Learn how to effectively interpret and utilize various attachments such as drawings, diagrams, and technical datasheets to enhance your specification process.

Valve Index: Appreciate the significance of valve indexing for accurate record-keeping, streamlined maintenance activities, and smooth piping system operations. Develop an understanding of how valve indexing functions within valve material specifications.

Valve Datasheets: Master the art of reading, interpreting, and creating valve datasheets. Discover the critical parameters to consider when selecting valves based on their specifications, materials, and performance characteristics.

Inspection Requirements: Comprehend the importance of inspection requirements in ensuring compliance with specifications, standards, and quality assurance. Familiarize yourself with the various testing and inspection methods employed during valve procurement and fabrication processes.

Material Section of Valves: Dive into the material section of valves, delving into the selection criteria for different materials. Explore the chemical and mechanical properties of materials like carbon steel, low-temperature carbon steel, stainless steel, and high-temperature carbon steel. Understand the relevant ASTM standards associated with each material type.

Anatomy of Gate Valves: Explore the anatomy of gate valves according to API standards. Gain knowledge about the 17 components specified by API 600, the 58 components specified by API 602, and the 14 components specified by API 6D and API 6A. Enhance your understanding of gate valves and their components.

API Standards: Discover the API standards applicable to valve material specifications, including API 600 and API 6D. Understand the requirements and guidelines outlined in these standards to ensure proper valve selection and material specifications.

Valve Trims and Non-Trims: Learn the material selection criteria for valve trims and non-trims. Explore the significance of selecting appropriate materials for valve internals to achieve optimal performance and durability.

Trims and Non-Trims Identifications: Master the methods and markings used to identify valve trims and non-trims. Understand how to interpret and recognize different trim materials based on industry standards and specifications.

Information Sources and Sequences: Gain insights into various sources of information available for valve material specifications. Understand the sequence of steps involved in extracting relevant clauses and tables from API standards and other reference documents.

Embark on the Valve Material Specification (VMS) course and emerge equipped with the knowledge and skills to create, interpret, and implement valve material specifications effectively as a proficient piping engineer.

Who this course is for:

- Piping Engineering

User Reviews

Rating

Atul Singla

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 73

- duration 10:32:19

- Release Date 2023/07/31