Introduction to safety in the chemical & process industries

WR Training

9:08:32

Description

Increase your awareness of chemical safety in the workplace and avoid the occurrence of unnecessary incidents

What You'll Learn?

- Raise your awareness and help you recognize early signs of safety concerns at your facility

- Promote the adoption of safe practices and operations to avoid the occurrence of unnecessary incidents

- Communicate lessons learned from previous accidents and avoid unnecessary safety incidents in the future

- Recognize safety signs used at your facility

- Understand the importance of evacuation diagrams

- Know the various types of fire extinguishers at your facility and how and when to use them

- Know the various types of work permits, their requirements and the principles that apply to them

- Recognize confined space hazards and the risks associated with this activity and how to manage them

- Recognize lifting operation hazards and the risks associated with this activity and how to manage them

- Recognize work at height space hazards and the risks associated with this activity and how to manage them

- Understand hazard label information

- Recognize hazard pictograms

- Learn how to interpret and use information on hazard labels and Safety Data Sheets (SDSs')

- Use Safety Data Sheets (SDSs') to find information on hazards and protective measures

- Increase your awareness of chemical safety in the workplace

- Recognize workplace chemical hazards and the risks associated with their use

- List conditions that may present an exposure risk and identify possible routes of exposure

- Demonstrate safety precautions that should be taken by workers and employers to minimize exposure to chemicals

- Demonstrate safe storage, transport, and disposal practices for hazardous chemicals

- Describe appropriate response actions in the event of a chemical incident

- Understand the need for Personal Protective Equipment (PPE) and how and when to use them

- Understand the concept of Boiling Liquid Expanding Vapor Explosions BLEVE

- Understand how a fire can cause a tank to BLEVE

- Know and understand the reasonable safe distances for emergency responders dealing with a potential BLEVE

- Understand the concept of Vapor Cloud Explosion (VCE)

Who is this for?

What You Need to Know?

More details

DescriptionWelcome to this introductory course on safety in the chemical and process industries.

This valuable 9 hour course is split into two separate modules.

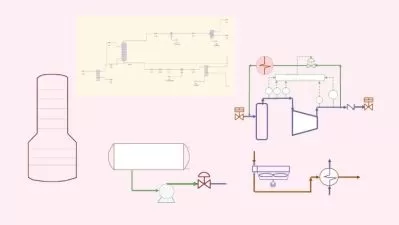

In the first module (section 1 through 7), permit-to-work systems, confined spaces, work at height and lifting operations are covered in detail to raise awareness around these activities and to promote the adoption of safe designs and practices to avoid the occurrence of unnecessary incidents.

The module then ends with a virtual plant safety tour. Now, while it is obviously impossible to address every safety mistake ever made, we have included in this virtual plant tour, a valuable summary of the most frequent mistakes encountered in the field. This will further raise your awareness so that you will be able to recognize early signs of safety concerns.

The second module (section 8 through 12) covers the required awareness training on the hazards common to the handling, storage, processing and use of chemicals, routinely found in refineries and chemical plants. These hazardous substances include:

Hydrogen sulphide (H2S)

Nitrogen (N2)

Hydrogen fluoride (HF)

Anhydrous ammonia (NH3)

Chlorine (Cl2)

Caustic soda (NaOH)

Acids

Liquefied Petroleum Gas (LPG)

…

For each hazardous substance, we will provide you with valuable insights into the measures you can take to protect yourself and your fellow workers, safe practices for storage and handling, and the correct response to emergency situations, involving incident events such as:

chemical spills

BLEVEs’ (Boiling Liquid Expanding Vapor Explosion)

VCEs’ (Vapor Cloud Explosion)

In addition, numerous real-world accidents from the Oil & Gas and chemical industries are presented and discussed in an easy-to-understand format, with the sole objective to communicate lessons learned and avoid unnecessary safety incidents in the future.

We are confident that this valuable course will help you contribute to the safety of your facility, your fellow workers and yourself.

We strongly recommend you take the time to watch this valuable course carefully. The usefulness of this course is not limited to operating people, there are many useful applications for the maintenance, design and construction of facilities.

Please feel free to share your experience with others, since this is one of the most effective means of communicating lessons learned and avoiding unnecessary incidents in the future.

Thank you for your interest in our online courses. Enjoy this valuable course and stay safe out there.

WRÂ Training

Spread the wings of your knowledge

NOTES

A high price has been paid for the information in this course: many workers and members of the public killed and billions of dollars worth of equipment destroyed. You get this information for the price of the course. It will be the best bargain you have ever received if you use the information to prevent similar unnecessary incidents at your facility.

This online course is intended as a safety supplement to your operator training courses, operating manuals, and operating procedures. It should not be treated as a substitute for them. It is provided to help you better understand the ‘why’ of safe operating practices and procedures in your plants. The advice in this course is a matter of opinion only and should not be construed as a representation or statement of any kind as to the effect of following such advice and no responsibility for the use of it can be assumed by WR Training.

Who this course is for:

- Operating personnel in refineries, petrochemical and chemical plants

- Process safety engineers & safety practitioners

- HSE Professionals

- Process, Chemical & Design engineers

- Technical Professionals dealing with risk assessment and integrity analysis

- Managers unfamiliar with Chemical Safety Management

- Senior managers wishing to refresh and consolidate Chemical Safety knowledge

Welcome to this introductory course on safety in the chemical and process industries.

This valuable 9 hour course is split into two separate modules.

In the first module (section 1 through 7), permit-to-work systems, confined spaces, work at height and lifting operations are covered in detail to raise awareness around these activities and to promote the adoption of safe designs and practices to avoid the occurrence of unnecessary incidents.

The module then ends with a virtual plant safety tour. Now, while it is obviously impossible to address every safety mistake ever made, we have included in this virtual plant tour, a valuable summary of the most frequent mistakes encountered in the field. This will further raise your awareness so that you will be able to recognize early signs of safety concerns.

The second module (section 8 through 12) covers the required awareness training on the hazards common to the handling, storage, processing and use of chemicals, routinely found in refineries and chemical plants. These hazardous substances include:

Hydrogen sulphide (H2S)

Nitrogen (N2)

Hydrogen fluoride (HF)

Anhydrous ammonia (NH3)

Chlorine (Cl2)

Caustic soda (NaOH)

Acids

Liquefied Petroleum Gas (LPG)

…

For each hazardous substance, we will provide you with valuable insights into the measures you can take to protect yourself and your fellow workers, safe practices for storage and handling, and the correct response to emergency situations, involving incident events such as:

chemical spills

BLEVEs’ (Boiling Liquid Expanding Vapor Explosion)

VCEs’ (Vapor Cloud Explosion)

In addition, numerous real-world accidents from the Oil & Gas and chemical industries are presented and discussed in an easy-to-understand format, with the sole objective to communicate lessons learned and avoid unnecessary safety incidents in the future.

We are confident that this valuable course will help you contribute to the safety of your facility, your fellow workers and yourself.

We strongly recommend you take the time to watch this valuable course carefully. The usefulness of this course is not limited to operating people, there are many useful applications for the maintenance, design and construction of facilities.

Please feel free to share your experience with others, since this is one of the most effective means of communicating lessons learned and avoiding unnecessary incidents in the future.

Thank you for your interest in our online courses. Enjoy this valuable course and stay safe out there.

WRÂ Training

Spread the wings of your knowledge

NOTES

A high price has been paid for the information in this course: many workers and members of the public killed and billions of dollars worth of equipment destroyed. You get this information for the price of the course. It will be the best bargain you have ever received if you use the information to prevent similar unnecessary incidents at your facility.

This online course is intended as a safety supplement to your operator training courses, operating manuals, and operating procedures. It should not be treated as a substitute for them. It is provided to help you better understand the ‘why’ of safe operating practices and procedures in your plants. The advice in this course is a matter of opinion only and should not be construed as a representation or statement of any kind as to the effect of following such advice and no responsibility for the use of it can be assumed by WR Training.

Who this course is for:

- Operating personnel in refineries, petrochemical and chemical plants

- Process safety engineers & safety practitioners

- HSE Professionals

- Process, Chemical & Design engineers

- Technical Professionals dealing with risk assessment and integrity analysis

- Managers unfamiliar with Chemical Safety Management

- Senior managers wishing to refresh and consolidate Chemical Safety knowledge

User Reviews

Rating

WR Training

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 163

- duration 9:08:32

- Release Date 2023/12/25