Introduction to Acceptance Sampling

Ray Harkins, The Manufacturing Academy,Michael J. Vella

1:44:53

Description

How to Balance Internal Inspection Costs with the Risk of Shipping Defective Parts

What You'll Learn?

- What is acceptance sampling and how is it used.

- The origins of acceptance sampling

- The advantages and disadvantages of acceptance sampling versus 100% inpsection

- Variables versus attributes

- The economic of acceptance sampling

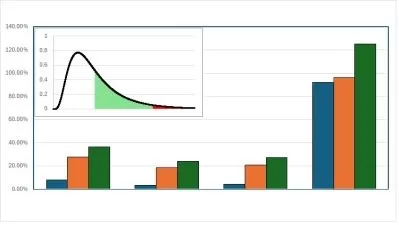

- AQL, LTPD, Operating Curves, Type I and II errors, and other key concepts

- How to build an OC in Microsoft Excel

- An Overview of Mil Standard 105E

- How to use the major sampling tables

- Single, double and multiple sampling case studies

Who is this for?

What You Need to Know?

More details

DescriptionThe decision of how much to inspect your parts before they ship to your customer is an important one. In the extremes, you could 1) inspect every part you ship or 2) not inspect any parts.

Option 1 would greatly reduces the number of defective parts you ship, but results in high internal inspection costs. Option 2 greatly reduces your internal sorting costs, but allows defective parts to flow right to your customers, resulting in dissatisfied customers and much high external sorting costs.

Acceptance Sampling offers an range of options in the middle. The basis for acceptance sampling is to inspect a sample of parts from a given lot, and then accepting or rejecting the lot based on the results of that sample inspection. Using Acceptance Sampling allows you to screen out the great majority of defective lots while minimizing your internal inspection costs.

"Introduction to Acceptance Sampling" offer you everything you need to start your own acceptance sampling system including:

Key terminology and concepts related to acceptance sampling

An overview of Mil Standard 105E

When and how Acceptance Sampling is best applied

The economics of acceptance sampling

What makes a good inspection plan

Type I and Type II errors and how they apply to inspection

Operating Characteristic Curves, OC Curves

How to build your own OC Curve in Microsoft Excel (Excel template included)

How to read and interpret sampling plan tables

Single, double, and multiple sampling plans

Normal, Tightened, and Reduced sampling plans

How and why to switch between sampling plans

Downloadable resources you can use at your workplace

When integrated into an organization's quality system alongside other powerful tools like Statistical Process Control (SPC), Layered Process Auditing (LPA), and Error Proofing, Acceptance Sampling can provide manufacturing organizations with a lower cost of high customer satisfaction.

If this is your goal, then "Introduction to Acceptance Sampling" is what you need. Sign up today!!

Who this course is for:

- Quality engineers, Quality managers, Quality technicians

- Industrial engineers, manufacturing engineers, process technicians

- Manufacturing managers

The decision of how much to inspect your parts before they ship to your customer is an important one. In the extremes, you could 1) inspect every part you ship or 2) not inspect any parts.

Option 1 would greatly reduces the number of defective parts you ship, but results in high internal inspection costs. Option 2 greatly reduces your internal sorting costs, but allows defective parts to flow right to your customers, resulting in dissatisfied customers and much high external sorting costs.

Acceptance Sampling offers an range of options in the middle. The basis for acceptance sampling is to inspect a sample of parts from a given lot, and then accepting or rejecting the lot based on the results of that sample inspection. Using Acceptance Sampling allows you to screen out the great majority of defective lots while minimizing your internal inspection costs.

"Introduction to Acceptance Sampling" offer you everything you need to start your own acceptance sampling system including:

Key terminology and concepts related to acceptance sampling

An overview of Mil Standard 105E

When and how Acceptance Sampling is best applied

The economics of acceptance sampling

What makes a good inspection plan

Type I and Type II errors and how they apply to inspection

Operating Characteristic Curves, OC Curves

How to build your own OC Curve in Microsoft Excel (Excel template included)

How to read and interpret sampling plan tables

Single, double, and multiple sampling plans

Normal, Tightened, and Reduced sampling plans

How and why to switch between sampling plans

Downloadable resources you can use at your workplace

When integrated into an organization's quality system alongside other powerful tools like Statistical Process Control (SPC), Layered Process Auditing (LPA), and Error Proofing, Acceptance Sampling can provide manufacturing organizations with a lower cost of high customer satisfaction.

If this is your goal, then "Introduction to Acceptance Sampling" is what you need. Sign up today!!

Who this course is for:

- Quality engineers, Quality managers, Quality technicians

- Industrial engineers, manufacturing engineers, process technicians

- Manufacturing managers

User Reviews

Rating

Ray Harkins, The Manufacturing Academy

Instructor's CoursesMichael J. Vella

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 27

- duration 1:44:53

- Release Date 2023/12/25