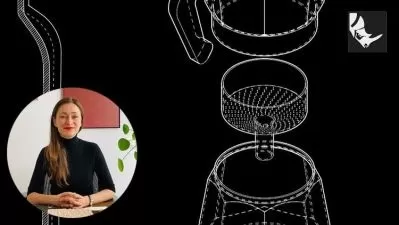

How to read technical drawings - from beginner to advanced

2:38:43

Description

Technical drawings - Read, interpret and use

What You'll Learn?

- How to orient yourself in a technical drawing

- Different types of lines used in a technical drawing

- Views, details and sections

- About the title block and what information it contains

- Functional and non functional dimensions

- Basic and auxiliary dimensions

- Location and form dimensions

- Modifiers

- Datums and target datums

- How to read automotive technical drawings

Who is this for?

What You Need to Know?

More details

DescriptionStruggling to understand technical drawings? Do you want to improve your communication and collaboration skills within technical teams? Search no more, this is the course for you.

Here is what you'll learn:

Fundamentals : Gain a solid understanding of the basics, including types of lines, angles of projection, views, details, sections, and identifiers.

Dimensioning Techniques: Master the rules of dimensioning, differentiate between functional, non-functional, auxiliary, and basic dimensions, and learn to apply special symbols effectively.

Datum Systems: Explore the concept of datums, their indication on drawings, datum systems, targets, and modifiers, including RPS and Best Fit methods.

Tolerance Analysis: Understand the importance of tolerances, their types, classes, standards, and applications for linear, angular, form, and location tolerances.

Modifier Mastery: Learn about various modifiers, including maximum and least material conditions, envelope and independency principles, Gauss, tangent, maximum inscribed, and minimum circumscribed.

Why choose this course:

This course is packed with real-world examples and exercises to help you apply your knowledge immediately.

Learn from an experienced professional that have deep understanding of technical drawing principles and practices.

This course guarantees a strong basis in technical drawing since it addresses all necessary subjects.

Study at your own pace with this online course, you'l find inside materials and interactive lessons.

Who this course is for:

- Quality Technicians, Quality Engineers

- Quality Project Engineers

- Project Managers

- Quality Managers

- Design Technicians, Design Engineers

- Process Technicians, Process Engineers

- CMM Technicians, CMM Engineers

- CNC Technicians, CNC Engineers

Struggling to understand technical drawings? Do you want to improve your communication and collaboration skills within technical teams? Search no more, this is the course for you.

Here is what you'll learn:

Fundamentals : Gain a solid understanding of the basics, including types of lines, angles of projection, views, details, sections, and identifiers.

Dimensioning Techniques: Master the rules of dimensioning, differentiate between functional, non-functional, auxiliary, and basic dimensions, and learn to apply special symbols effectively.

Datum Systems: Explore the concept of datums, their indication on drawings, datum systems, targets, and modifiers, including RPS and Best Fit methods.

Tolerance Analysis: Understand the importance of tolerances, their types, classes, standards, and applications for linear, angular, form, and location tolerances.

Modifier Mastery: Learn about various modifiers, including maximum and least material conditions, envelope and independency principles, Gauss, tangent, maximum inscribed, and minimum circumscribed.

Why choose this course:

This course is packed with real-world examples and exercises to help you apply your knowledge immediately.

Learn from an experienced professional that have deep understanding of technical drawing principles and practices.

This course guarantees a strong basis in technical drawing since it addresses all necessary subjects.

Study at your own pace with this online course, you'l find inside materials and interactive lessons.

Who this course is for:

- Quality Technicians, Quality Engineers

- Quality Project Engineers

- Project Managers

- Quality Managers

- Design Technicians, Design Engineers

- Process Technicians, Process Engineers

- CMM Technicians, CMM Engineers

- CNC Technicians, CNC Engineers

User Reviews

Rating

Udemy

View courses Udemy- language english

- Training sessions 32

- duration 2:38:43

- Release Date 2025/02/25