Explore Basics, Read Piping & Instrumentation Diagrams P&ID

Boostrand Training

1:49:54

Description

Explore P&ID details typically shown, piping, equipment and instrument symbols, types, workflow, and issuance purposes

What You'll Learn?

- Workflow of P&ID issuance and its role in a project

- Details shown on a P&ID for piping, fittings, instruments, scope definition, ...etc.

- Anatomy of the P&ID

- P&ID types such as legend, typical details, distribution and tie-in P&IDs

- Issuance purposes of P&IDs and the details shown depending on the purpose

Who is this for?

What You Need to Know?

More details

DescriptionSo maybe you are dealing with P&IDs, you find yourself overwhelmed with lots of details, symbols and notes and you need to understand what all this means, but still don't know how to start?

If you're new to process engineering or want to boost your knowledge about how things work in industrial plants, then this course is perfect for you.

What Will You Learn?

P&IDs are the lifeblood of process engineering, and understanding them is essential for anyone involved in plant design, operation, or maintenance.

In this course, we'll help you understand P&IDs by covering these important topics:

Distinguishing P&IDs from PFDs: We begin by unraveling the differences between P&IDs and Process Flow Diagrams (PFDs). We shall see how the P&ID is based on the PFD and how the P&ID is expected to show much more details.

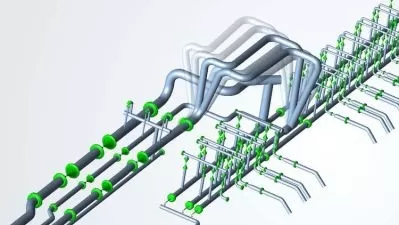

Understanding P&ID Symbols: P&IDs are packed with information, from main pipe data and equipment specifics to valves, fittings, instrumentation, and control and shutdown systems. In this course, we shall talk about how each of these elements is reflected on the P&IDs.

Types of P&IDs: Including legend, distribution, tie-in P&IDs, and package P&IDs. We delve deep into these types, offering real-world examples of when and how these are applied.

Project Workflow: P&IDs are integral to the project lifecycle. This means that the P&ID is affected by the data provided from upstream documents such as PFD. In addition, P&IDs shall also affect the whole engineering activities afterwards such as piping or instrumentation activities. In addition, the level of detail of data in a P&ID shall highly differ depending on the project stage. We shall talk about all this in the course.

Our course is all about practical knowledge. You'll learn how different details are expected to be shown on a P&ID and their implications. By the end, you'll feel confident reading P&IDs and spotting problems early on.

Don't miss out on this chance to explore the basics of P&IDs and boost your skills in process engineering.

Are you ready to embark on a journey into the world of P&IDs?

Enroll today, and let's start!

Who this course is for:

- Chemical Engineering Student Looking for Learning Practical Engineering Concepts

- Process Engineers looking for enhancing their P&ID Preparation Skills

- Plant Operation Engineers willing to understand the behind-the-scene concepts of plant design and share solutions to enhance the safety and operability of your plant.

- Non-Process Engineers for example, a piping or instrumentation or mechanical engineer who wants to understand the criticality of process engineering requirements and how your role affects the plant performance

So maybe you are dealing with P&IDs, you find yourself overwhelmed with lots of details, symbols and notes and you need to understand what all this means, but still don't know how to start?

If you're new to process engineering or want to boost your knowledge about how things work in industrial plants, then this course is perfect for you.

What Will You Learn?

P&IDs are the lifeblood of process engineering, and understanding them is essential for anyone involved in plant design, operation, or maintenance.

In this course, we'll help you understand P&IDs by covering these important topics:

Distinguishing P&IDs from PFDs: We begin by unraveling the differences between P&IDs and Process Flow Diagrams (PFDs). We shall see how the P&ID is based on the PFD and how the P&ID is expected to show much more details.

Understanding P&ID Symbols: P&IDs are packed with information, from main pipe data and equipment specifics to valves, fittings, instrumentation, and control and shutdown systems. In this course, we shall talk about how each of these elements is reflected on the P&IDs.

Types of P&IDs: Including legend, distribution, tie-in P&IDs, and package P&IDs. We delve deep into these types, offering real-world examples of when and how these are applied.

Project Workflow: P&IDs are integral to the project lifecycle. This means that the P&ID is affected by the data provided from upstream documents such as PFD. In addition, P&IDs shall also affect the whole engineering activities afterwards such as piping or instrumentation activities. In addition, the level of detail of data in a P&ID shall highly differ depending on the project stage. We shall talk about all this in the course.

Our course is all about practical knowledge. You'll learn how different details are expected to be shown on a P&ID and their implications. By the end, you'll feel confident reading P&IDs and spotting problems early on.

Don't miss out on this chance to explore the basics of P&IDs and boost your skills in process engineering.

Are you ready to embark on a journey into the world of P&IDs?

Enroll today, and let's start!

Who this course is for:

- Chemical Engineering Student Looking for Learning Practical Engineering Concepts

- Process Engineers looking for enhancing their P&ID Preparation Skills

- Plant Operation Engineers willing to understand the behind-the-scene concepts of plant design and share solutions to enhance the safety and operability of your plant.

- Non-Process Engineers for example, a piping or instrumentation or mechanical engineer who wants to understand the criticality of process engineering requirements and how your role affects the plant performance

User Reviews

Rating

Boostrand Training

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 40

- duration 1:49:54

- Release Date 2023/12/15