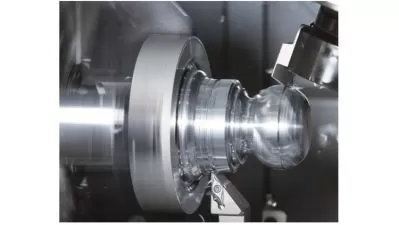

Control Valve Maintenance and Troubleshooting

Mahendra Singh

2:24:08

Description

Control Valve Types and Styles, Selection Considerations, International Standards & Valve Sizing

What You'll Learn?

- Control Valve Fundamentals

- Control Valve Types and Styles

- Control Valve installation, Setup and Calibration

- Valve and Actuator Sizing and Selection criteria's

- International Standards for Control Valves

- Control valve Problem ,Troubleshooting, Maintenance & Repair

Who is this for?

What You Need to Know?

More details

DescriptionCOURSE OVERVIEW

This course is designed to provide participants with the working knowledge on several of control valves, control valve sizing and its characteristics. The course covers procedures on how to conduct a regular inspection and maintenance of control valves. It consists of lectures and extensive practical exercises on control valve repair and calibration using the specific tools and testing equipment.

COURSE OBJECTIVE

The objective of the program is producing engineers, plant tech, plant operator and plant personnel with a good skill and knowledge so that they can operating plant for optimum level.

COURSE OUTCOMES

At the end of the course, the participants should be able to:-

Explain control valve terminology.

Describe the following flow characteristics for valve type selection.

Describe the control valve parts.

Size a control valve for liquid, gas and steam service.

Repair and calibrate different types of control valves.

Describe the working principle of positioner and I/P converter.

Calibrate Smart Control Valve / Smart Positioner.

COURSE CONTENTS

Overview of control valve and their parts.

Types of control valve

Valve terminologist and specification.

Control valve characteristics

Seat leakage classifications.

Control Valve applications.

Materials consideration

Control valve sizing

Actuators, types, selection and application.

Control valve accessories.

Assembling and disassembling of control valve

Control valve leak test using test rig equipment.

Operation of Smart Positioner

Who this course is for:

- Plant or process supervisors, team leaders, instrument engineers, lectures, and others who need to upgrade the knowledge and a comprehensive review or new experience of control valve technology.

COURSE OVERVIEW

This course is designed to provide participants with the working knowledge on several of control valves, control valve sizing and its characteristics. The course covers procedures on how to conduct a regular inspection and maintenance of control valves. It consists of lectures and extensive practical exercises on control valve repair and calibration using the specific tools and testing equipment.

COURSE OBJECTIVE

The objective of the program is producing engineers, plant tech, plant operator and plant personnel with a good skill and knowledge so that they can operating plant for optimum level.

COURSE OUTCOMES

At the end of the course, the participants should be able to:-

Explain control valve terminology.

Describe the following flow characteristics for valve type selection.

Describe the control valve parts.

Size a control valve for liquid, gas and steam service.

Repair and calibrate different types of control valves.

Describe the working principle of positioner and I/P converter.

Calibrate Smart Control Valve / Smart Positioner.

COURSE CONTENTS

Overview of control valve and their parts.

Types of control valve

Valve terminologist and specification.

Control valve characteristics

Seat leakage classifications.

Control Valve applications.

Materials consideration

Control valve sizing

Actuators, types, selection and application.

Control valve accessories.

Assembling and disassembling of control valve

Control valve leak test using test rig equipment.

Operation of Smart Positioner

Who this course is for:

- Plant or process supervisors, team leaders, instrument engineers, lectures, and others who need to upgrade the knowledge and a comprehensive review or new experience of control valve technology.

User Reviews

Rating

Mahendra Singh

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 46

- duration 2:24:08

- Release Date 2023/09/10