Collection of Chemical Engineering Excel Workbooks & Folders

WR Training Pro

1:23:48

Description

Assess flow & properties of fluids, calculate pressure drop, size pipe, valves heat exchangers & centrifugal compressors

What You'll Learn?

- FLOW OF FLUIDS EXCEL WORKBOOK

- Determine the main physical properties of fluids (viscosity, vapor pressure, specific gravity, weight density...)

- Assess the theory of flow in pipe : Laminar vs Turbulent flow

- Use the Bernoulli Theorem to calculate pressure drop, head loss or flow velocity

- Calculate the pressure drop "dP" and the head loss "hL" through any piping system

- Determine the friction factor "f" of any piping system

- Calculate the flow of compressible and incompressible fluids in pipe

- Calculate the resistance coefficient "K" of any piping component (pipes, valves, bends, reducers, Tees, Wyes...)

- Calculate the flow coefficient "Cv" of a control valve and use it in assessing flows and pressure drops

- Size and select a control valve when designing and operating any piping system for both gases and liquids

- Calculate the flow of compressible and incompressible fluids through Orifice Plates, Flow Nozzles and Venturi Meters

- Size and select a flow meter when designing and operating any piping system for both gases and liquids

- CHEMICAL ENGINEER'S REFERENCE FOLDER

- Physical characteristics of pure substances

- Vapor pressure data, charts & diagrams

- Physical properties of water and steam

- Specific heat data, charts & diagrams

- Enthalpy data, charts & diagrams

- Viscosity data, charts & diagrams

- Thermal conductivity data, charts & diagrams

- Density of liquids data, charts & diagrams

- Behavior of gases and compression

- Liquid–Vapor equilibrium data, charts & diagrams

- Combustion data, charts & diagrams

- Fluid dynamics data, charts & diagrams

- Centrifugal pumps data, charts & diagrams

- Heat transfer and heat exchangers data, charts & diagrams

- Compressors data, charts & diagrams

- Properties relative to the petroleum cuts data, charts & diagrams

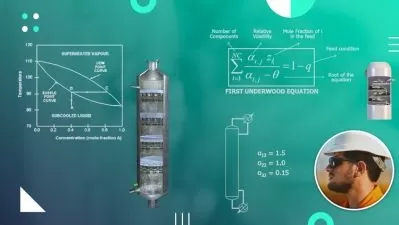

- Distillation, absorption and stripping data, charts & diagrams

- Safety data, charts & diagrams

- SIZING VALVES EXCEL WORKBOOK

- Be more innovative in your solutions to valve and control valve problems

- Have an organized approach to the procedure of valve sizing in accordance with the ANSI & ISA recommendations

- Be able to size valves for any flow conditions likely to be found in a process plant

- Have a general notion about the confidence to be placed in the sizing result conclusions

- HEAT EXCHANGER DESIGN AND CALCULATION EXCEL WORKBOOK

- Design and analyze the performance of your heat exchanger in a professional manner with this valuable Excel Workbook

- Select the appropriate shell and tube heat exchanger for your application

- Get access to valuable shell and tube heat exchanger design tables according to DIN 21184 - 21191 and TEMA std to properly design shell and tube heat exchangers

- Get access to useful charts and diagrams to solve daily heat exchanger problems

- CENTRIFUGAL COMPRESSOR PERFORMANCE ASSESSMENT EXCEL WORKBOOK

- Understand and predict your centrifugal compressor behavior and performance

- Optimize the operation efficiency of your centrifugal compressor

- Assess the effect of one inlet condition change on your compressor performance

- Assess the effect of multiple inlet conditions changes on your compressor performance

- Assess the effect of your system resistance on your compressor performance

- Adjust your centrifugal compressor rated performance curve to your actual inlet conditions

- Know and use the useful Fan-Law relationships

Who is this for?

What You Need to Know?

More details

DescriptionDear students,

This special course will give you access to a collection of valuable chemical engineering Excel workbooks:

1. Flow of Fluids Excel Workbook

2. The Chemical Engineer's Reference Folder

3. Valve Sizing Excel Workbook

4. Heat Exchanger Design & Calculation Excel Workbook

5. Centrifugal Compressor Performance & Behavior Excel Workbook

6. Centrifugal Pump Excel Workbook

The video lectures included in this materiel are quick tutorials to show you how to use these valuable tools.

Please watch these videos and follow the instructions provided.

In case of any problem, feel free to ask us for help in the Q&A section.

Enjoy these valuable tools.

-----------------------------

1. FLOW OF FLUIDS EXCEL WORKBOOK

Flow of Fluids Excel Workbook simulates the operation of small piping systems transporting liquids and industrial gases under a variety of operating conditions.

Flow of Fluids Excel Workbook is based on industry recognized principles and standards from ASME, HI, IEC, AWWA, ISA, and ANSI...

Flow of Fluids Excel Workbook is easy-to-use and has a highly intuitive user interface.

Flow of Fluids Excel Workbook presents formulas and data for :

1. Physical properties determination for a variety of fluids (specific gravity, viscosity, vapor pressure...)

2. Pressure drop and head loss calculations through pipes, fittings and valves

3. Flow calculations for incompressible and compressible fluids through pipes, fittings, valves and pumps

4. Sizing piping systems for incompressible and compressible fluids

5. Flow resistance coefficients calculations for pipes, fittings and valves

6. Flow calculations for incompressible and compressible fluids through flow meters (Orifice Plates, Nozzles and Venturi meters)

7. Centrifugal pump calculation (Pump head, NPSH, Specific speed, affinity laws…)

8. Converting variables and process parameters to a numerious alternative units of measurement

-----------------------------

2. THE CHEMICAL ENGINEER'S REFERENCE FOLDER

This unique folder provides well-organized technical data in form of comprehensive tables, charts and diagrams.

324 pages including more than 90 tables, 120 charts and 70 diagrams which are essential to the Oil & Gas, Petrochemical and Chemical Industries.

The preparation of this folder was a joint effort of WR training engineers who compiled data, charts and diagrams for which they were especially qualified and possess valuable experience.

What topics are covered in this engineering folder:

These comprehensive charts and diagrams cover many important engineering fields:

- physical characteristics of pure substances

- vapor pressure

- physical properties of water and steam

- specific heat

- enthalpy

- viscosity

- thermal conductivity

- density of liquids

- behaviour of gases and compression

- liquid – vapor equilibrium

- combustion

- fluid dynamics

- centrifugal pumps

- heat transfer and heat exchangers

- compressors

- properties relative to the petroleum cuts

- distillation, absorption and stripping

- safety

- conversion tables

-----------------------------

3. VALVE SIZING EXCEL WORKBOOK

The Valve Sizing Excel Spreadsheet provides well organized technical data in form of spreadsheet calculations indispensible for anyone involved in the sizing of valves. It presents formulae and data for :

Valve flow coefficients Cv

Flow of fluids through valves

Pressure drop through valves and attached fittings

Valve Reynolds Number calculations

Predicting maximum flow through valves in choked conditions

Representative values of valve capacity factors

And more...

The spreadsheet includes two worksheets :

Sizing for liquids (incompressible fluids)

Non vaporizing flow conditions

Choked flow conditions

Sizing for vapors and gases (compressible fluids)

-----------------------------

4. HEAT EXCHANGER EXCEL WORKBOOK

This Heat Exchanger Excel Workbook provides well organized technical data in form of spreadsheet calculations, tables, charts and diagrams, indispensible for anyone involved in the design, selection, operation, maintenance or inspection of heat exchangers.

This Excel workbook presents formulae and data for :

Physical properties of the most common fluids used in heat exchangers in Oil & Gas, Petroleum, Refining and Chemical processes

Heat transfer coefficients "U" and "α"

Pressure losses in shell and tube heat exchangers (tube + shell sides)

Useful shell and tube geometrical calculations

Geometrical data of shell and tube heat exchangers according to DIN 28184 & 28191 and TEMAÂ Standards

Guidelines for the selection of shell and tube heat exchangers

Thermal conductivity of the most common material of construction of shell and tube heat exchangers

Valuable heat exchanger charts, figures and diagrams

Numerous conversion tables

And more...

-----------------------------

5. CENTRIFUGAL COMPRESSOR EXCEL WORKBOOK

This workbook provides qualitative and quick comparisons and application notes for centrifugal compressors. It describes calculations and procedures to predict performance characteristics, especially head, discharge pressure and power.

This valuable Excel workbook presents formulas and data for:

General centrifugal compressor calculations

Assessing the effect of one inlet condition change on compressor performance

Assessing the effect of multiple inlet condition changes on compressor performance

Assessing the effect of system resistance on compressor performance

Adjusting centrifugal compressor rated performance curve to actual inlet conditions

Useful Fan-Law relationships

Valuable charts and diagrams for centrifugal compressors

Conversion tables

-----------------------------

DOWNLOAD INSTRUCTIONS

1. Upon enrolling in, expand the last section "DOWNLOADABLE RESOURCES"

2. Under the lecture "Download me", click on the folder "Resources" => A list of the Excel Workbooks will appear

3. Click on any Workbook

4. A download window will pop-up. Select the location where you want to save the file

5. Once downloaded and saved on your computer, you can start using these valuable tools

IMPORTANT NOTES:

We assume that Microsoft Excel is installed on your computer and that you have basic knowledge of using Excel

All Excel Workbooks mentioned above include Visual Basic for Application function subroutines (VBA). Macros must be enabled for them to work

DISCLAIMER

All Excel Workbooks mentioned above are provided by WR Training "as is" and any express or implied warranties, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no event shall the Copyright owner or contributors be liable for any direct, indirect, incidental, special, exemplary, or consequential damages (including, but not limited to, procurement of substitute goods or services, loss of use, data, or profits, or business interruption) however caused and on any theory of liability, whether in contract, strict liability, or tort (including negligence or otherwise) arising in any way out of the use of this spreadsheet, even if advised of the possibility of such damage.

Who this course is for:

- Chemical, Process, Petroleum Engineers

- Design Engineers

- Piping Engineers

- Plant Engineers

- Facility Managers

- Maintenance Technicians

- Mechanics

- Plant Operators

- Safety Engineers

- Recent College Graduates

Dear students,

This special course will give you access to a collection of valuable chemical engineering Excel workbooks:

1. Flow of Fluids Excel Workbook

2. The Chemical Engineer's Reference Folder

3. Valve Sizing Excel Workbook

4. Heat Exchanger Design & Calculation Excel Workbook

5. Centrifugal Compressor Performance & Behavior Excel Workbook

6. Centrifugal Pump Excel Workbook

The video lectures included in this materiel are quick tutorials to show you how to use these valuable tools.

Please watch these videos and follow the instructions provided.

In case of any problem, feel free to ask us for help in the Q&A section.

Enjoy these valuable tools.

-----------------------------

1. FLOW OF FLUIDS EXCEL WORKBOOK

Flow of Fluids Excel Workbook simulates the operation of small piping systems transporting liquids and industrial gases under a variety of operating conditions.

Flow of Fluids Excel Workbook is based on industry recognized principles and standards from ASME, HI, IEC, AWWA, ISA, and ANSI...

Flow of Fluids Excel Workbook is easy-to-use and has a highly intuitive user interface.

Flow of Fluids Excel Workbook presents formulas and data for :

1. Physical properties determination for a variety of fluids (specific gravity, viscosity, vapor pressure...)

2. Pressure drop and head loss calculations through pipes, fittings and valves

3. Flow calculations for incompressible and compressible fluids through pipes, fittings, valves and pumps

4. Sizing piping systems for incompressible and compressible fluids

5. Flow resistance coefficients calculations for pipes, fittings and valves

6. Flow calculations for incompressible and compressible fluids through flow meters (Orifice Plates, Nozzles and Venturi meters)

7. Centrifugal pump calculation (Pump head, NPSH, Specific speed, affinity laws…)

8. Converting variables and process parameters to a numerious alternative units of measurement

-----------------------------

2. THE CHEMICAL ENGINEER'S REFERENCE FOLDER

This unique folder provides well-organized technical data in form of comprehensive tables, charts and diagrams.

324 pages including more than 90 tables, 120 charts and 70 diagrams which are essential to the Oil & Gas, Petrochemical and Chemical Industries.

The preparation of this folder was a joint effort of WR training engineers who compiled data, charts and diagrams for which they were especially qualified and possess valuable experience.

What topics are covered in this engineering folder:

These comprehensive charts and diagrams cover many important engineering fields:

- physical characteristics of pure substances

- vapor pressure

- physical properties of water and steam

- specific heat

- enthalpy

- viscosity

- thermal conductivity

- density of liquids

- behaviour of gases and compression

- liquid – vapor equilibrium

- combustion

- fluid dynamics

- centrifugal pumps

- heat transfer and heat exchangers

- compressors

- properties relative to the petroleum cuts

- distillation, absorption and stripping

- safety

- conversion tables

-----------------------------

3. VALVE SIZING EXCEL WORKBOOK

The Valve Sizing Excel Spreadsheet provides well organized technical data in form of spreadsheet calculations indispensible for anyone involved in the sizing of valves. It presents formulae and data for :

Valve flow coefficients Cv

Flow of fluids through valves

Pressure drop through valves and attached fittings

Valve Reynolds Number calculations

Predicting maximum flow through valves in choked conditions

Representative values of valve capacity factors

And more...

The spreadsheet includes two worksheets :

Sizing for liquids (incompressible fluids)

Non vaporizing flow conditions

Choked flow conditions

Sizing for vapors and gases (compressible fluids)

-----------------------------

4. HEAT EXCHANGER EXCEL WORKBOOK

This Heat Exchanger Excel Workbook provides well organized technical data in form of spreadsheet calculations, tables, charts and diagrams, indispensible for anyone involved in the design, selection, operation, maintenance or inspection of heat exchangers.

This Excel workbook presents formulae and data for :

Physical properties of the most common fluids used in heat exchangers in Oil & Gas, Petroleum, Refining and Chemical processes

Heat transfer coefficients "U" and "α"

Pressure losses in shell and tube heat exchangers (tube + shell sides)

Useful shell and tube geometrical calculations

Geometrical data of shell and tube heat exchangers according to DIN 28184 & 28191 and TEMAÂ Standards

Guidelines for the selection of shell and tube heat exchangers

Thermal conductivity of the most common material of construction of shell and tube heat exchangers

Valuable heat exchanger charts, figures and diagrams

Numerous conversion tables

And more...

-----------------------------

5. CENTRIFUGAL COMPRESSOR EXCEL WORKBOOK

This workbook provides qualitative and quick comparisons and application notes for centrifugal compressors. It describes calculations and procedures to predict performance characteristics, especially head, discharge pressure and power.

This valuable Excel workbook presents formulas and data for:

General centrifugal compressor calculations

Assessing the effect of one inlet condition change on compressor performance

Assessing the effect of multiple inlet condition changes on compressor performance

Assessing the effect of system resistance on compressor performance

Adjusting centrifugal compressor rated performance curve to actual inlet conditions

Useful Fan-Law relationships

Valuable charts and diagrams for centrifugal compressors

Conversion tables

-----------------------------

DOWNLOAD INSTRUCTIONS

1. Upon enrolling in, expand the last section "DOWNLOADABLE RESOURCES"

2. Under the lecture "Download me", click on the folder "Resources" => A list of the Excel Workbooks will appear

3. Click on any Workbook

4. A download window will pop-up. Select the location where you want to save the file

5. Once downloaded and saved on your computer, you can start using these valuable tools

IMPORTANT NOTES:

We assume that Microsoft Excel is installed on your computer and that you have basic knowledge of using Excel

All Excel Workbooks mentioned above include Visual Basic for Application function subroutines (VBA). Macros must be enabled for them to work

DISCLAIMER

All Excel Workbooks mentioned above are provided by WR Training "as is" and any express or implied warranties, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose are disclaimed. In no event shall the Copyright owner or contributors be liable for any direct, indirect, incidental, special, exemplary, or consequential damages (including, but not limited to, procurement of substitute goods or services, loss of use, data, or profits, or business interruption) however caused and on any theory of liability, whether in contract, strict liability, or tort (including negligence or otherwise) arising in any way out of the use of this spreadsheet, even if advised of the possibility of such damage.

Who this course is for:

- Chemical, Process, Petroleum Engineers

- Design Engineers

- Piping Engineers

- Plant Engineers

- Facility Managers

- Maintenance Technicians

- Mechanics

- Plant Operators

- Safety Engineers

- Recent College Graduates

User Reviews

Rating

WR Training Pro

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 22

- duration 1:23:48

- Release Date 2023/08/21