Catia V5 Electrical Harness Design - Automotive Projects

Alexander Consulting

10:16:57

Description

Learn automotive electrical harness design from an engineer with more than 18 years experience

What You'll Learn?

- Electrical Harness Design Process from A to Z

- Electrical Harness Manufacturing Process

- Electrical Harness materials and components in automotive

- Harness design rules, requirements and challenges

- The basics for selecting harness components like: connectors, wires, relays, fuses, splices and others

- Practice projects where we implement what we learn

- Many other concepts and secrets in automotive electrical harness design

- Learn how to create a portfolio, CV and how to conduct yourself at an interview

- Advices and info for the Electrical Harness Design interview

Who is this for?

What You Need to Know?

More details

DescriptionHi

My name is Alex, and I am a Design Engineer.

I have been working for more than 18 years with Catia V5 in automotive engineering, racing and industrial design.

All the knowledge and experience that I gained helped me work with companies like

Ferrari Formula One Team, Red Bull Racing, Jaguar Land Rover, Aston Martin and others

In this course I will show you how to design electrical harnesses for automotive companies.

I will explain what is the design process for electrical harnesses and what materials and components are being used.

I will also explain what are the design rules and what requirements automotive companies have for harness design

Next, I will reveal what is the criteria for selecting electrical components for harnesses like: connectors, pins, wires, relays, fuses, splices and others

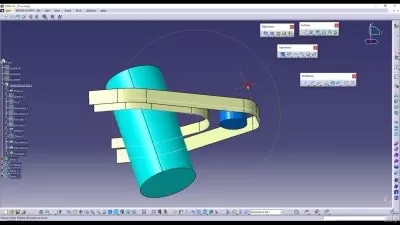

After all this theory we will design a few CAD projects where we implement everything we learned and I will give you a few assignments and challenges.

After the projects we will make a few small projects to touch on more harness design techniques that you need to know

I design with Catia V5 but you can design this in any other CAD software as I provide step files.

In the last section of the course, we discuss about how to tailor your CV, how to conduct yourself at an interview and how to create a portfolio

With all of this said. This course is a cheat code.

To be able to take chance on opportunities you need experience, and experience is built only with practice.

Thanks for watching this video and see you in the course.

Who this course is for:

- Aspiring Electrical Harness Designers

- Aspiring EDS Designers (this is NOT a complete EDS/circuit/diagram design course)

- Non electrical students that want to become Electrical Harness designers (you need to learn basic electricity on your own)

- Any Designer or Engineer that wants to know more about this industry

Hi

My name is Alex, and I am a Design Engineer.

I have been working for more than 18 years with Catia V5 in automotive engineering, racing and industrial design.

All the knowledge and experience that I gained helped me work with companies like

Ferrari Formula One Team, Red Bull Racing, Jaguar Land Rover, Aston Martin and others

In this course I will show you how to design electrical harnesses for automotive companies.

I will explain what is the design process for electrical harnesses and what materials and components are being used.

I will also explain what are the design rules and what requirements automotive companies have for harness design

Next, I will reveal what is the criteria for selecting electrical components for harnesses like: connectors, pins, wires, relays, fuses, splices and others

After all this theory we will design a few CAD projects where we implement everything we learned and I will give you a few assignments and challenges.

After the projects we will make a few small projects to touch on more harness design techniques that you need to know

I design with Catia V5 but you can design this in any other CAD software as I provide step files.

In the last section of the course, we discuss about how to tailor your CV, how to conduct yourself at an interview and how to create a portfolio

With all of this said. This course is a cheat code.

To be able to take chance on opportunities you need experience, and experience is built only with practice.

Thanks for watching this video and see you in the course.

Who this course is for:

- Aspiring Electrical Harness Designers

- Aspiring EDS Designers (this is NOT a complete EDS/circuit/diagram design course)

- Non electrical students that want to become Electrical Harness designers (you need to learn basic electricity on your own)

- Any Designer or Engineer that wants to know more about this industry

User Reviews

Rating

Alexander Consulting

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 50

- duration 10:16:57

- English subtitles has

- Release Date 2022/11/22