Basics of Heat Exchanger Design, Operation & Inspection

Process Engineering Hacks

2:29:30

Description

Learn the Principles, Design Considerations of Heat Exchanger Design

What You'll Learn?

- Types of Heat Exchangers

- Causes of failure in heat exchangers

- Heat exchangers design considerations

- Good practices to avoid fouling

- Heat transfer basics

- Box Cooler / Bayonet. Cooler

- Shell & Tube heat exchanger

- TEMA nomenclature

- AEW type heat exchanger

- BEM type heat exchanger BEU type heat exchanger AET/S type heat exchanger BKU type he

- BEU type heat exchanger

- AET/S type heat exchanger

- BKU type heat exchanger

- Tube-side flow allocation

- Exchanger component description covering tubes, shell and baffle

- How to use HTRI software?

Who is this for?

What You Need to Know?

More details

DescriptionHeat Exchangers are part and parcel of the process plants. Â The design of heat exchangers is always done by specialists in an EPC company or in vendor office. Most of the time such people conduct only exchanger design.

However, a process engineer, mechanical engineer or a plant operations professional may be required understand and exchanger design, specify an exchanger or trouble shoot an exchanger operation. They need to have an overall understanding of the design, construction, operation of the equipment in order to be effective.

This course is intended to equip people intending to be in such positions of responsibility.

The course contents are as below

Introduction to Heat Exchangers

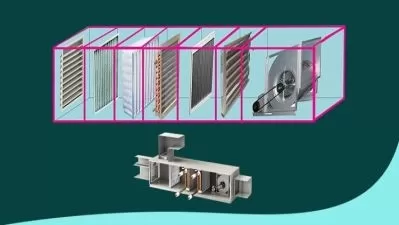

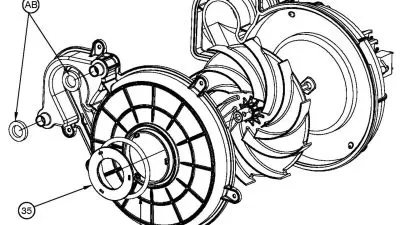

Types of Heat Exchangers

Causes of failure in heat exchangers

Heat exchangers design considerations

Good practices to avoid fouling

Heat transfer basics

Box Cooler / Bayonet. Cooler

Shell & Tube heat exchanger

Welded plate type heat exchanger

TEMA nomenclature,

AEW type heat exchanger

AEP type heat exchanger

BEM type heat exchanger

BEU type heat exchanger

AET/S type heat exchanger

BKU type heat exchanger

Exchanger basic components description

Exchanger basic components: tubes

Exchanger basic components: shell

Exchanger basic components: baffle

Tube-side flow allocation

How to use HTRI software?

Causes of failure in heat exchangers

More content with regard to operation, construction and inspection will be added soon.

Who this course is for:

- Anyone who is curious about heat exchanger design, operation

Heat Exchangers are part and parcel of the process plants. Â The design of heat exchangers is always done by specialists in an EPC company or in vendor office. Most of the time such people conduct only exchanger design.

However, a process engineer, mechanical engineer or a plant operations professional may be required understand and exchanger design, specify an exchanger or trouble shoot an exchanger operation. They need to have an overall understanding of the design, construction, operation of the equipment in order to be effective.

This course is intended to equip people intending to be in such positions of responsibility.

The course contents are as below

Introduction to Heat Exchangers

Types of Heat Exchangers

Causes of failure in heat exchangers

Heat exchangers design considerations

Good practices to avoid fouling

Heat transfer basics

Box Cooler / Bayonet. Cooler

Shell & Tube heat exchanger

Welded plate type heat exchanger

TEMA nomenclature,

AEW type heat exchanger

AEP type heat exchanger

BEM type heat exchanger

BEU type heat exchanger

AET/S type heat exchanger

BKU type heat exchanger

Exchanger basic components description

Exchanger basic components: tubes

Exchanger basic components: shell

Exchanger basic components: baffle

Tube-side flow allocation

How to use HTRI software?

Causes of failure in heat exchangers

More content with regard to operation, construction and inspection will be added soon.

Who this course is for:

- Anyone who is curious about heat exchanger design, operation

User Reviews

Rating

Process Engineering Hacks

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 48

- duration 2:29:30

- Release Date 2024/02/09