Apply HAZOP, SIL & Process Safety Practices on P&ID Design

Boostrand Training

2:20:51

Description

Analyze layers of protection of equipment, piping, and system against safety and operational issues by HAZOP & SIL study

What You'll Learn?

- P&ID guidelines for Process Safety

- Analyze plant layers of protection

- Warn the Operator to respond against upsets through Alarms

- Prevent Hazard by Process / System Shutdown

- Mitigate Hazard using Process Safety Valves

- Proper Equipment Design Conditions to Ensure Inherently Safe Operation

- Control and Shutdown Valve Fail Safe Positions

- HAZOP and SIL Assessment of a P&ID

Who is this for?

What You Need to Know?

More details

DescriptionAre you passionate about ensuring the safety and reliability of industrial processes? Do you want to master the art of safeguarding piping, equipment, and systems against unforeseen challenges and process upsets? If so, our comprehensive course on process safety is your key to success.

Course Highlights:

Understand the vital role of process safety in industrial settings.

Explore methods to protect your plant against a wide range of scenarios, from power failures to fire incidents.

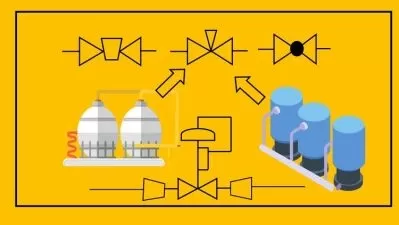

Learn how to incorporate safety measures into Piping and Instrumentation Diagrams (P&IDs).

Discover how to specify the proper design pressure and temperature of our equipment, piping, and systems.

Explore the layers of protection, including alarms, shutdown systems, and pressure safety valves (PSV), in preventing process upsets.

Delve into the world of Hazard and Operability (HAZOP) study and understand how it's conducted on a P&ID to enhance process safety.

Dive into Safety Integrity Level (SIL) analysis and how to ensure that our layers of protection are addressing potential process deviations through a risk assessment related to the hazard severity and likelihood (frequency).

Our engaging course includes video lectures, practical examples, quizzes, and interactive discussions. You'll have the opportunity to apply your knowledge to real-world scenarios.

Ready to discover the realm of Process Safety? Enroll Now!

Secure your spot and join us in ensuring safer industrial processes for a sustainable future. Don't miss this opportunity to master process safety and take your career to new heights.

Who this course is for:

- Chemical Engineering students and fresh graduates

- Process Engineers looking for enhancing their P&ID Preparation Skills

- Plant Operation Engineers willing to understand the behind-the-scene concepts of plant design and share solutions to enhance the safety and operability of your plant.

- Non-Process Engineers for example, instrumentation or mechanical engineer who wants to understand the criticality of process engineering requirements and how your role affects the plant performance

Are you passionate about ensuring the safety and reliability of industrial processes? Do you want to master the art of safeguarding piping, equipment, and systems against unforeseen challenges and process upsets? If so, our comprehensive course on process safety is your key to success.

Course Highlights:

Understand the vital role of process safety in industrial settings.

Explore methods to protect your plant against a wide range of scenarios, from power failures to fire incidents.

Learn how to incorporate safety measures into Piping and Instrumentation Diagrams (P&IDs).

Discover how to specify the proper design pressure and temperature of our equipment, piping, and systems.

Explore the layers of protection, including alarms, shutdown systems, and pressure safety valves (PSV), in preventing process upsets.

Delve into the world of Hazard and Operability (HAZOP) study and understand how it's conducted on a P&ID to enhance process safety.

Dive into Safety Integrity Level (SIL) analysis and how to ensure that our layers of protection are addressing potential process deviations through a risk assessment related to the hazard severity and likelihood (frequency).

Our engaging course includes video lectures, practical examples, quizzes, and interactive discussions. You'll have the opportunity to apply your knowledge to real-world scenarios.

Ready to discover the realm of Process Safety? Enroll Now!

Secure your spot and join us in ensuring safer industrial processes for a sustainable future. Don't miss this opportunity to master process safety and take your career to new heights.

Who this course is for:

- Chemical Engineering students and fresh graduates

- Process Engineers looking for enhancing their P&ID Preparation Skills

- Plant Operation Engineers willing to understand the behind-the-scene concepts of plant design and share solutions to enhance the safety and operability of your plant.

- Non-Process Engineers for example, instrumentation or mechanical engineer who wants to understand the criticality of process engineering requirements and how your role affects the plant performance

User Reviews

Rating

Boostrand Training

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 46

- duration 2:20:51

- Release Date 2023/12/13