14 Components of API 6D Valve

Atul Singla

1:11:26

Description

Anatomy of API 6D Gate Valves

What You'll Learn?

- Brief of API 6D

- Salient features of API 6D

- Scope of API 6D

- 14 Components of API 6D Gate Valves

Who is this for?

More details

DescriptionAPI 6D is a standard developed by the American Petroleum Institute (API) that sets requirements for the design, manufacture, testing, and documentation of pipeline and piping system gate valves. This course aims to provide a comprehensive understanding of API 6D gate valves, their scope, salient features, and components.

Scope of API 6D Gate Valves: API 6D gate valves are designed for use in oil and gas production, transportation, and refining industries. These valves are primarily used to control the flow of fluids through pipelines and piping systems. The scope of API 6D gate valves includes design, manufacturing, testing, and documentation requirements for valves that meet API 6D specifications.

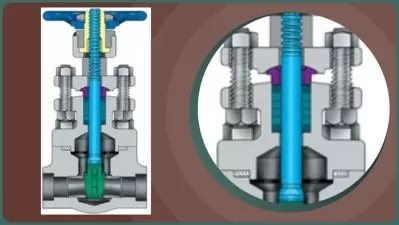

Components of API 6D Gate Valves: API 6D gate valves are composed of several key components, including:

Body: The body of API 6D gate valves is the outer casing that contains the other components.

Bonnet: The bonnet of API 6D gate valves is the cover that is attached to the body and contains the stem and packing.

Stem: The stem of API 6D gate valves is the component that connects the actuator to the gate and controls the movement of the gate.

Gate: The gate of API 6D gate valves is the component that controls the flow of fluid through the valve.

Seats: The seats of API 6D gate valves are the surfaces against which the gate seals to prevent leakage.

Packing: The packing of API 6D gate valves is the material that seals the stem to prevent leakage.

Actuator: The actuator of API 6D gate valves is the component that controls the movement of the stem and gate.

Students will learn the following:

The scope of API 6D gate valves and their importance in the oil and gas industry.

The salient features of API 6D gate valves, include their double block and bleed capability, full-bore design, metal-to-metal sealing, anti-static devices, and fire-safe design.

The components of API 6D gate valves, include the body, bonnet, stem, gate, seats, packing, and actuator.

The design, manufacturing, testing, and documentation requirements of API 6D gate valves.

The applications and uses of API 6D gate valves in various industries, including oil and gas production, transportation, and refining.

The importance of safety considerations when using API 6D gate valves, including the prevention of fluid leakage and the mitigation of static electricity and fire risks.

Who this course is for:

- Mechanical Engineers

API 6D is a standard developed by the American Petroleum Institute (API) that sets requirements for the design, manufacture, testing, and documentation of pipeline and piping system gate valves. This course aims to provide a comprehensive understanding of API 6D gate valves, their scope, salient features, and components.

Scope of API 6D Gate Valves: API 6D gate valves are designed for use in oil and gas production, transportation, and refining industries. These valves are primarily used to control the flow of fluids through pipelines and piping systems. The scope of API 6D gate valves includes design, manufacturing, testing, and documentation requirements for valves that meet API 6D specifications.

Components of API 6D Gate Valves: API 6D gate valves are composed of several key components, including:

Body: The body of API 6D gate valves is the outer casing that contains the other components.

Bonnet: The bonnet of API 6D gate valves is the cover that is attached to the body and contains the stem and packing.

Stem: The stem of API 6D gate valves is the component that connects the actuator to the gate and controls the movement of the gate.

Gate: The gate of API 6D gate valves is the component that controls the flow of fluid through the valve.

Seats: The seats of API 6D gate valves are the surfaces against which the gate seals to prevent leakage.

Packing: The packing of API 6D gate valves is the material that seals the stem to prevent leakage.

Actuator: The actuator of API 6D gate valves is the component that controls the movement of the stem and gate.

Students will learn the following:

The scope of API 6D gate valves and their importance in the oil and gas industry.

The salient features of API 6D gate valves, include their double block and bleed capability, full-bore design, metal-to-metal sealing, anti-static devices, and fire-safe design.

The components of API 6D gate valves, include the body, bonnet, stem, gate, seats, packing, and actuator.

The design, manufacturing, testing, and documentation requirements of API 6D gate valves.

The applications and uses of API 6D gate valves in various industries, including oil and gas production, transportation, and refining.

The importance of safety considerations when using API 6D gate valves, including the prevention of fluid leakage and the mitigation of static electricity and fire risks.

Who this course is for:

- Mechanical Engineers

User Reviews

Rating

Atul Singla

Instructor's Courses

Udemy

View courses Udemy- language english

- Training sessions 7

- duration 1:11:26

- Release Date 2023/04/25